Re-engineering the F-35 with two engines would be anything but the straightforward improvement that the President said. It would be roughly a whole redesign of the aircraft.” These are the words of ex-Air Force Secretary Frank Kendall, highlighting an ongoing debate in fighter design: the safety and reliability of single-engine vs. twin-engine designs, a debate re-sparked by President Trump’s 2025 comments supporting a two- or even four-engine F-35. To aerospace engineers and defense commentators, the F-35’s dependence on a single Pratt & Whitney F135 turbofan is not just a political slogan it is a study in the balance between performance, survivability, and the constant pursuit of cutting-edge technology.

1. The Single-Engine Problem: Safety, Survivability, and Public Opinion

The F-35 Lightning II is nearly unique among large multirole fighters in being powered by a single engine. Whereas the F-16 can also operate on a single engine, its mission profile and smaller size distinguish it. The selection of the F-35’s engine was not taken lightly. Pratt & Whitney claims the F135 is “more than an order of magnitude better than previous generations of fighter engines” in terms of safety over its life cycle, citing fewer parts and a simpler architecture, as well as aggressive digital health monitoring.

Nevertheless, the threat of catastrophic engine failure remains in public and political debate, enhanced by the F-35’s high visibility and publicity for any accident. But as fleet statistics demonstrate, the crash rate of the F-35 is not statistically higher than its contemporaries; instead, its accidents are more heavily publicized because the F-35 is the world’s most manufactured advanced fighter.

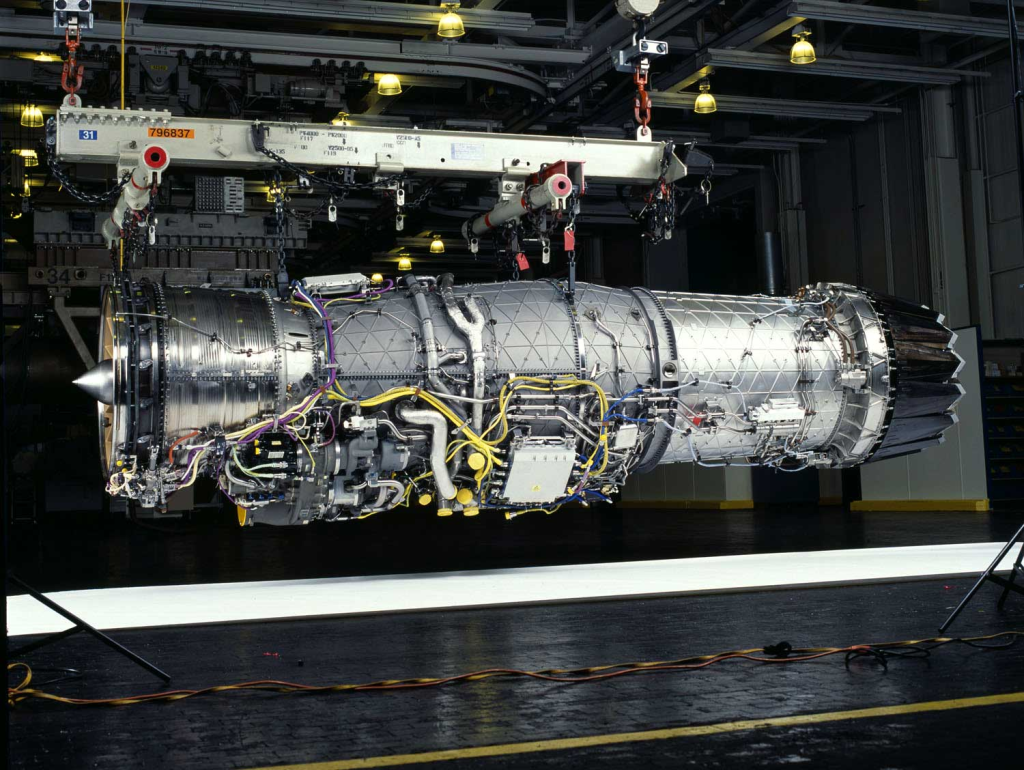

2. Engineering the F135: Power, Efficiency, and Stealth

The F135 afterburning turbofan, which is based on the F119 that drives the F-22, has 43,000 pounds of afterburner thrust and approximately 28,000 pounds in military power. Its design focuses not only on sheer power but also on fuel efficiency and thermal management key to maximizing range and reducing the aircraft’s infrared signature. The F135’s design facilitates the F-35’s stealth by controlling heat and merging with the airframe to minimize detectability, a radical contrast to Russian designs such as the Su-57 that still lag behind in providing engines with similar low-observable capabilities. The digital health management system of the engine offers maintainers real-time data to allow predictive maintenance and swift troubleshooting, a step change from conventional scheduled or reactive methods.

3. STOVL Ingenuity: The F135-PW-600 and the F-35B’s Lift System

The F135 cannot be mentioned without discussing the short takeoff and vertical landing (STOVL) capability of the F-35B. The F135-PW-600 variant has a rotating exhaust nozzle and is integrated with the Rolls-Royce LiftSystem to allow the aircraft to hover and land vertically. The lift fan generates 46% of the downward thrust, the vectoring nozzle another 46%, and wing nozzles the remaining 8%. Test pilot Phil “Rowdy” Yates characterized the system as taking “17 miracles to come together,” a tribute to the engineering sophistication of the F-35B’s operational versatility. This STOVL solution played a critical role in Lockheed Martin’s defeat of Boeing’s X-32, which was based on existing Harrier technology.

4. Maintenance, Reliability, and the Digital Revolution

While the F135 is technologically impressive, the F-35 fleet has struggled with enduring reliability and availability issues. During fiscal year 2023, the average monthly availability of the fleet was 51 percent substantially less than the 65 percent goal, with full mission capable rates for combat-coded aircraft as low as 48 percent during 2023. The digital health management system of the engine, based on prognostic and health management (PHM) approaches, provides condition-based maintenance, using real-time sensor inputs to anticipate failures and better tailor repair schedules by means of advanced algorithms. But readiness has been hindered by problems with the legacy Autonomic Logistics Information System (ALIS) and supply chain chokepoints particularly for F135 spare parts. The transition to the cloud-based Operational Data Integrated Network (ODIN) holds out the hope of better, but integration delays continue.

5. The Engine Core Upgrade: Achieving Block 4 and Beyond

With the cancelling of the Adaptive Engine Transition Program (AETP) for the F-35, Pratt & Whitney’s Engine Core Upgrade (ECU) is now the key to future-proofing the fleet. The ECU will put the F135 back on full life, boost power and cooling capability, and accommodate the advanced sensors and weapons of the Block 4 configuration. As Pratt & Whitney describes, the ECU “will deliver the first F135 ECU-powered F-35 to the warfighter in 2029 and provide meaningful capability by the end of the decade” with increased digital adaptive controls and 10x more processing power for real-time optimization. The upgrade is retrofit-friendly and compatible across all F-35 variants, allowing global operators to enjoy the improvements.

6. Sixth-Generation Horizon and Adaptive Cycle Engines

Though the F135 ECU stretches the F-35’s shelf life, the future of propulsion belongs to adaptive cycle engines. General Electric and Pratt & Whitney are both working on three-stream adaptive engines through the Next Generation Adaptive Propulsion (NGAP) program with an eye towards sixth-generation fighter aircraft. These engines offer up to 20% more thrust, 25% improved fuel efficiency, and more than 30% greater range than today’s technology. Ceramic-matrix composites and 3D-printed parts promote greater operating temperatures and longevity, and the third bypass stream provides pilots with the ability to alternate between high-thrust and fuel-saving modes. With projected electrical power output at one megawatt, these engines will power advanced sensors, electronic warfare, and even directed-energy weapons.

7. The Persistent Challenge: Reliability, Availability, and Oversight

With regard to technological progress, the F-35 program’s operational realities are nevertheless sobering. Depot repair times for major components, including the F135, have averaged 141 days more than double the Pentagon’s target. Critical shortages of engines, canopies, and sensors have kept aircraft grounded, while the logistics footprint for forward deployment exceeds original requirements, complicating rapid response scenarios. Congressional oversight has struggled to keep pace, with classified reports and compressed review timelines limiting effective scrutiny. As one oversight report pointed out, “It’s unacceptable that the F-35 can’t meet even these modest requirements” for operational test reliability and maintainability.

The F-35 propulsion narrative is therefore one of the astonishing engineering feat hemmed in by the pragmatics of operational sophistication, maintenance logistics, and the changing requirements of the future of air-to-air combat. The F135, continuously being upgraded, is still a technological wonder, but the takeaways are already making their mark on the engines and expectations of the next generation.