What happens when the world’s most ambitious fighter jet meets the hard edge of a union contract dispute? “IAM Union members delivered a clear message: the proposal from Boeing Defense fell short of addressing the priorities and sacrifices of the skilled workforce,” declared the International Association of Machinists and Aerospace Workers. For the F-47 program America’s next-generation air dominance platform this standoff is more than a labor story. It’s a test of whether cutting-edge engineering can outpace the realities of production lines, budgets, and global rivals.

1. Labor Tensions and Production Risks

More than 3,200 union members at Boeing’s defense facilities in Missouri and Illinois have rejected what the company called “the richest contract offer we’ve ever presented to IAM 837.” With the contract set to expire and no new talks scheduled, Boeing is bracing for a potential strike. Dan Gillian, vice-president of Boeing Air Dominance, confirmed, “We’re disappointed our employees voted down the richest contract offer which addressed all their stated priorities.” The specter of a walkout looms large, especially after last year’s seven-week strike in Seattle crippled key Boeing assembly plants. The Midwest facilities are not only vital for legacy platforms like the F-15 and F/A-18 but are now central to the F-47’s accelerated build plan. As automated manufacturing and AI become more central to Boeing’s manufacturing process, the ability of the company to hold onto qualified personnel as well as embracing new-age technologies will take precedence Boeing has employed robotics, machine vision systems, artificial intelligence analytics, and digital twins to enhance manufacturing efficiency as well as product quality.

2. F-47: The Technical Leap Forward

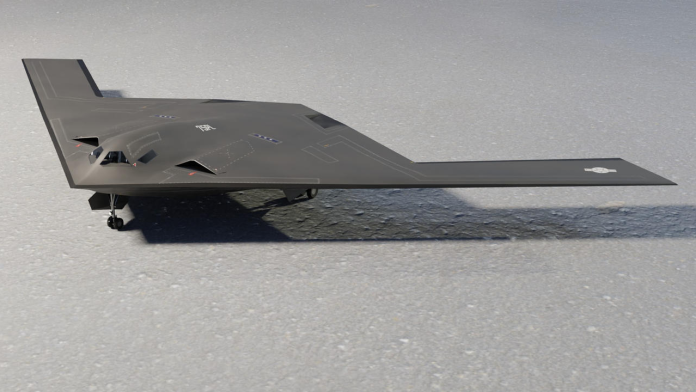

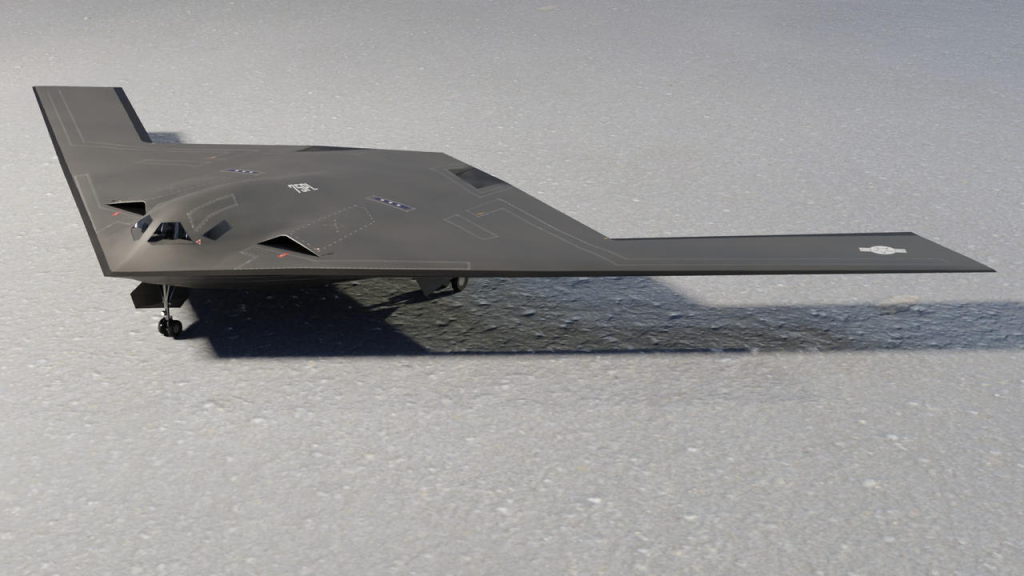

The sleek F-47, constructed through the Next Generation Air Dominance (NGAD) program, is the world’s first manned sixth-generation fighter, with President Trump describing it as “virtually unseeable” and boasting of its unmatched maneuverability, thrust, and unique ability to control drone swarms. Renderings indicate a stealthy, angular appearance with canard wings and flattened fuselage, differing from fifth-generation aircraft. Air Force Chief of Staff General David Allvin emphasized, “The F-47 will be part of the Air Force sixth-gen fleet. along with the B-21 bomber. with next-generation stealth, sensor fusion, and long-range strike for countering the most advanced threats in contested environments.” The expected combat range of the jet is more than 1,000 nautical miles, a quantum more than the F-35C’s 670 and the Super Hornet’s 600-plus. The F-47’s “Stealth++” nomenclature suggests virtual invisibility from radar, with active camouflage and improved heat suppression the F-47 will be nearly invisible to radar, no matter the aspect.

3. Manned-Unmanned Teaming: Constructing the Future of Air Warfare

Perhaps the most revolutionary aspect is the F-47’s integration with Collaborative Combat Aircraft (CCA) autonomous “loyal wingman” drones that can extend range and survivability of the fighter. Trump explained that the jet can fly “with as many drones as you want.” The Air Force will purchase more than 1,000 CCAs, with the F-47 acting as a “swarm commander.” The drones will perform everything from missile interdiction to deep-strike missions, all guided in real time by the pilot. This manned-unmanned teaming (MUM-T) system is a complex engineering challenge that necessitates secure, high-bandwidth data links, robust AI, and stealthy sensor fusion AI-powered vision systems inspect fuselage sections for cracks, misalignments, and irregularities. In the opinion of one expert, “Manned-unmanned teaming is the future of air combat and recent exercises and demonstrations have shown it being critical to enabling increased combat effects while minimizing risks to pilots.”

4. Production Processes: Smart Factories and Human Intelligence

Boeing’s transition to “smart factories” is the basis of the F-47’s condensed development cycle. Robotics drilling, automated painting, and digital twin simulations are what the company uses to streamline production and minimize mistakes. These technologies have reduced assembly time up to 50% for primary components and improved defect detection with quality control using AI. Boeing utilizes digital twins to create virtual models of planes and manufacturing processes ahead of physical building. Integration of automation in no way diminishes the contribution of skilled machinists especially considering the F-47’s modular open-systems architecture, which demands flexibility and precision. The current labor dispute raises the question of the thin line between technological advancement and employee stability.

5. Budget and Oversight Issues

The potential of F-47 comes at a high cost. The unit costs per aircraft are to be $300 million, which is three times that of the F-35. Congressional overseers have raised an eyebrow over the Air Force’s practice of co-mingling NGAD and CCA budgets, making oversight more difficult and raising questions about transparency. The co-mingling of two major acquisition programs restricted Congress’s ability to monitor the way funds were being spent between NGAD and CCA initiatives.

The House Appropriations Committee is requesting that funding have separate lines and more frequent briefings, and the cost-control focus would be by the Trump administration’s Department of Government Efficiency, led by Elon Musk. With other high-priority competitions like the B-21 Raider and Minuteman III replacement, the fate of the F-47 hinges on continued political and fiscal backing.

6. International Competition: The Sixth-Generation Race

The F-47 is not the only one competing in the battle for air supremacy. Europe’s Tempest (Italy, Japan, UK) and France-Germany-Spain’s FCAS are also building their own sixth-generation planes, each emphasizing open architectures, scalable autonomy, and digital manufacturing. China’s J-20 program and purported sixth-gen activity and Russia’s Su-57 modernization underscore the global competition.

Notably, China has invested heavily in the indigenous development of engines and AI, while Europe’s Tempest is chasing operational capability in 2035 with a modularity and ease of upgrade emphasis the Tempest FACS has some characteristics, including; Open and flexible physical architecture to allow incorporation of future innovations and different mission sets. The exportability of the F-47 albeit in “lighter models” may decide alliances and industrial partnerships for generations.

7. Engineering and Program Management Challenges

The F-47’s tight timeline first flight scheduled before 2029 mandates flawless delivery on both engineering and program management sides. The Air Force has “unprecedented design maturity,” with X-plane test models logging hundreds of hours to minimize risk on new tech. But experience says that advanced fighter development programs rarely deliver on schedule and under budget. As one industry analysis notes, “While every new generation of fighter planes is designed to be more efficient than its predecessor and typically is, it cannot achieve a really drastic savings in cost.” The twin ghosts of cost inflation and labor unrest still haunt it.

As the countdown to the contract and the world holds its breath, the fate of the F-47 will be decided as much in the bargaining room on the factory floor as in the breakthroughs in the design laboratory. The next air-supremacy chapter may hinge on whether Boeing is able to close the gap between digital accuracy and human craftsmanship before the competition, and the clock, do.