“Built like a tank” it’s a phrase that will probably evoke husky SUVs or rugged sedans, but to a few American automakers, it was a more-than-figurative expression. They didn’t merely earn their reputation as rugged; they went on to construct tanks right off their assembly lines, reshaping the direction of 20th-century war.

When the rest of the world was on the verge of war in the two World Wars, Detroit best-traded chrome for metal and horsepower for fire. The outcome? A legacy of machines that won battles but have also gone on to become symbols of American ingenuity. This listicle is a journey into the most interesting tanks ever produced by American automakers, the engineering marvels within their bonnets, and the untold stories behind the steel monsters that make them immortal.

1. Buick’s M18 Hellcat: The Quickest Cat on the Field

The Buick M18 Hellcat was not only posing in hopes of being quick it was the quickest tracked armored vehicle of the World War period, reaching a whopping 60 mph on the highways, even outpacing current tanks such as the M1 Abrams. Buick’s styling, under Harley Earl’s direction, departed from traditional thinking in favor of speed and maneuverability over armor, creating a tank destroyer that could out-run panzers and perform daring hit-and-run tactics. The Continental R975 nine-cylinder radial engine of the Hellcat produced 400 hp and 940 lb-ft torque, with a Torqmatic automatic transmission and a torsion bar suspension still in use on modern armor.

In spite of thinning armor and open turret, which exposed crews to snipers and shrapnel, Hellcat’s combat record was excellent. In one engagement, a column of more than 30 German tanks was ambushed by five Hellcats, burning 19, and losing just two of their own. M18’s speed and firepower allowed it to “run circles around German tanks,” as MotorTrend said, and its innovative maintenance design allowed crews to change engines in the field. Only 2,507 Hellcats were built, but their impact dwarfed their numbers, with the type being used in Europe as well as in the Pacific and postwar fighting from Italy to the Balkans.

2. Cadillac’s M5 Stuart and M24 Chaffee: Luxury Engineering Goes to War

Cadillac, the luxury marque, was a major manufacturer of World War II light tanks. The M5 Stuart, using twin Cadillac V8 engines and GM Hydra-Matic transmissions, was both simple to maintain and reliable. Cadillac manufactured more than 5,300 M5 and M5A1 tanks, and sent thousands of engines to other plants. The 220 hp M5 engine and heavy-duty construction helped make it the favorite of Allied soldiers.

But the M24 Chaffee was the one that best summed up Cadillac’s engineering talent. Replacing the antiquated Stuart, the Chaffee had a very sloping armor design and a 75 mm gun developed from the B-25 bomber weapons system, which provided firepower equivalent to much heavier tanks. Its torsion bar suspension and twin Cadillac V8s provided a top speed of 33.6 mph with a range of almost 100 miles. Crews praised the Chaffee for its “greater firepower over the Stuart’s earlier 37 mm gun,” and it proved sufficiently versatile to be utilized in wars far into the Cold War, Korea to Algeria.

3. Ford’s GAA V8 and the M4A3 Sherman: Powering the Arsenal of Democracy

Ford’s own contribution to armored warfare was nothing if not revolutionary. The firm’s GAA V8 engine, initially borrowed from a V12 configuration to meet Rolls-Royce Merlin competition, went on to become the pulsing heart of the M4A3 Sherman, the backbone of the U.S. armored force. The 1,100 cubic inch all-aluminum V8 engine produced 500 hp and 1,050 lb-ft of torque, the most advanced and dependable tank engine of its time. Ford’s design turned out to be so durable that the Shermans powered by it continued to serve with the U.S. Army several years after the war.

Ford’s Willow Run factory became legendary in scale and pace, producing not only tanks but also B-24 Liberator bombers in quantities to amaze doubters. The Richmond plant was a major hub for tank final assembly and conversion of military trucks to ship off to the Pacific. The M4A3’s reliability and performance earned it the approval of crews, and its engine design would shape American armored vehicles for decades to come.

4. Chrysler’s M1 Abrams: The Edge of Modern Tank Design

The history of the M1 Abrams testifies to the ingenuity of American know-how and to the aggressive battle among car makers. Chrysler Defense, now General Dynamics, secured the contract for the U.S. Army’s new main battle tank following a cliffhanger competition with General Motors. The Abrams incorporated a gas turbine powerplant that could burn more than one fuel type, Chobham composite armor, and an electronic fire control system innovations that raised levels of survival and killing to new dimensions.

With its 1,500 hp Honeywell AGT1500 turbine and high-tech 120 mm smoothbore cannon, the Abrams became an icon of American military superiority. Its composite armor featuring classified layers of depleted uranium made it virtually invulnerable to most anti-tank missiles and guns. As “Coffee or Die” claimed, Abrams’ “unprecedented longevity” and flexibility have cemented it as the state-of-the-art pinnacle of armored warfare for more than four decades with thousands of its systems still in use and ongoing upgrades maintaining it combat-capable.

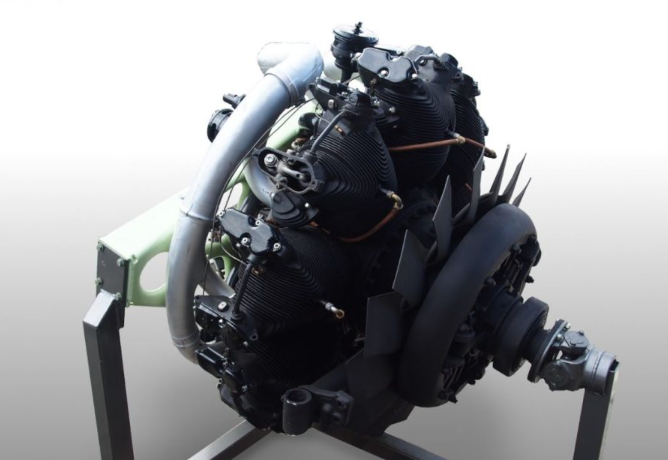

5. The Continental R-975: The Unsung Hero Behind Several American Tanks

As the builders basked in the glory, Continental Motors toiled largely behind the scenes to power a gargantuan portion of America’s armored force inventory. The R-975 radial engine, originally an airplane engine, was converted to power the M4 and M4A1 Sherman tanks, the M18 Hellcat, and countless self-propelled guns. At its height, Continental built more than 54,000 R-975 engines, which made it the backbone of American armored mobility in every World War II theater.

The ruggedness and maintainability of the R-975 were the stuff of legend, as combat units could service tanks in the field in the worst of conditions. Its application in the M18 Hellcat, where it was mounted with a provision for easy removal and field servicing, demonstrated the versatility of this engine. The legacy of the engine endured beyond World War II and continued to influence the design of subsequent tank engines for American forces, ensuring that Continental’s contribution to victory would never be forgotten.

America’s transition into tank manufacturing wasn’t an afterthought in history but was instead a climactic chapter of warfighting and of engineering greatness. From Buick’s Hellcat record-breaker to the still-going-strong punch of the M1 Abrams, these beasts are a creative mix of industrial power, outside-the-box problem-solving, and the never-say-die requirement to out-screw the enemy. For auto enthusiasts and military historians in general, the legacy of these tanks is proof that, sometimes, the ultimate test of an automaker’s metal is not on the open road, but on the battlefield.