A semi-auto pistol is meant to be an issue solved: feed, fire, extract, repeat. Once such a loop is broken, the shooter is left with an object of metal or polymer that may prove to be as much of an inconvenience as it does a genuine danger.

The infamous American design flops in the history of design seldom collapse due to the same cause. They accumulate little errors: small errors, doddery springs, clumsy controls, cracking parts, and the reliability and safe handling are compromised. These pistols are like a reminder of what can happen when engineering margins are too razed in an age in which internal mechanisms (like firing pin blocks) are widely considered.

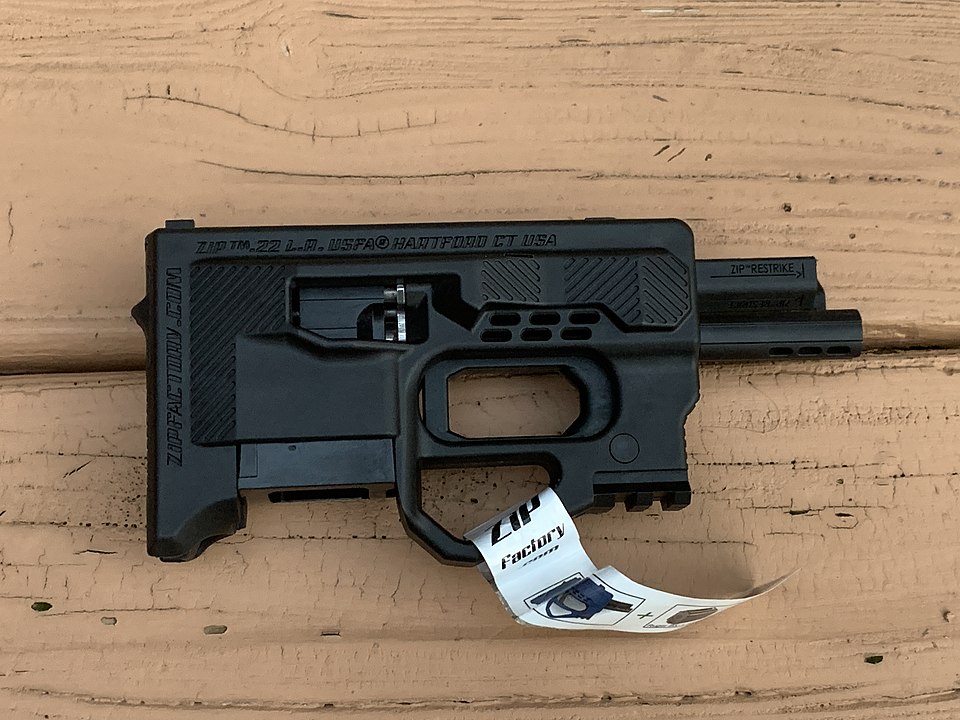

1. USFA Zip .22

The Zip .22 was futuristic when going modular and ended up shaped more like a plastic utility box than a useful handgun. It was characterized by its defining hazard, which is human-factors induced: the charging handles were close to the muzzle, which made fingers want to creep into the worst place imaginable in case of malfunction clearance. Combine the frequent jamming and a trigger system that never gave one a sense of safety, and the platform was an example of how different can become dangerous within no time.

2. Raven Arms MP-25

The MP-25 of Raven made the formula of the disposable pocket pistol popular, small, cheap, and based on zinc alloy. What was a problem was that soft material and loose tolerances are not cosmetic problems in a firearm; they are service-life and safety problems. It was found by the owners to wear quickly and reported striker system that could slip given the possibility of the drop of the pistol, and the safety lever itself was often cited as engaging intermittently.

3. Remington R51 (2014 relaunch)

The rebirth was of a modern version of a classic, yet initial guns came out with crude internal finishes and a diet of failures to feed and extract. Maintenance, which generally builds back confidence, became in itself a challenge as the disassembly/reassembly was notoriously challenging. The result was massive recall and a lesson to be learnt forever; brand heritage does not replace production preparedness.

4. Jennings J-22

One of the instruments that gained its fame in the archaic manner is the J-22, which attracted constant failures combined with weak parts. Extractors have often been referred to as low-grade components that broke at the beginning of the service of the pistol. Ergonomics compounded this, the slide, which is also known to bite the web of the hand, is an avoidable route of injury, and is supposed to be blocked with good grip geometry and a real beavertail.

5. Lorcin L380

The L380 is known to be heavy-looking and at the same time incredibly delicate in the unsuitable locations. Cases of broken zinc frames particularly at stress points such as the barrel lug area place it on the list of pistols that may deteriorate not slowly but suddenly. Its safety also received a lot of criticism because it was too easy to bump off when carrying, a failure mode that was minimized by the modern passive systems.

6. Two shot derringer-style (DoubleTap Defense)

The tradeoffs made by putting large-bore power into an ultra-thin two-shot format could not be concealed once it was discharged. Recoil was sufficiently penal to retard recovery and the process of reloading was in itself slow two facts which come into collision with the realities of defensive shooting. The heavy-pulling trigger and narrow grip profile of the platform finished the image of what seemed to be a more innovative than helpful concept.

7. Davis Industries P-32

A point that is always raised about the P-32 is that it is not a gun but rather a cautionary sign. One of the major mechanical phobias was centered on the slide retention method: a simple pin might shear, and the slide can slide in the opposite direction. Even magazine construction was also criticized and the sheet metal was thin and therefore deformed and caused feed failures. Safety issues were also related to the firing pin whereby there are warnings against protrusion and slam-fire.

8. Heizer Defense Pocket AR

By squeezing a single shot of.223 into 1 shot pistol, one would have produced a flash of muzzle blast and concussion with a very short barrel, and an impressive fireball that hurt the senses. The loss of velocity eliminated most of the features that make the cartridge appealing in longer platforms and noise and flash remain the sole distinguishing features. The scanty sight rendered tact instead of art after point-blank.

9. Kimber Solo

The Solo appeared the part of a high-end micro-compact, though the dependability was pegged on the choice of ammunition. The pistol had earned a reputation of being fussy and had a lot of malfunction even when it was fed on loads the maker liked. The disassembly needed to operate the tools also made it less attractive to owners who use a carry gun as a device that has to be easily accessible and serviced.

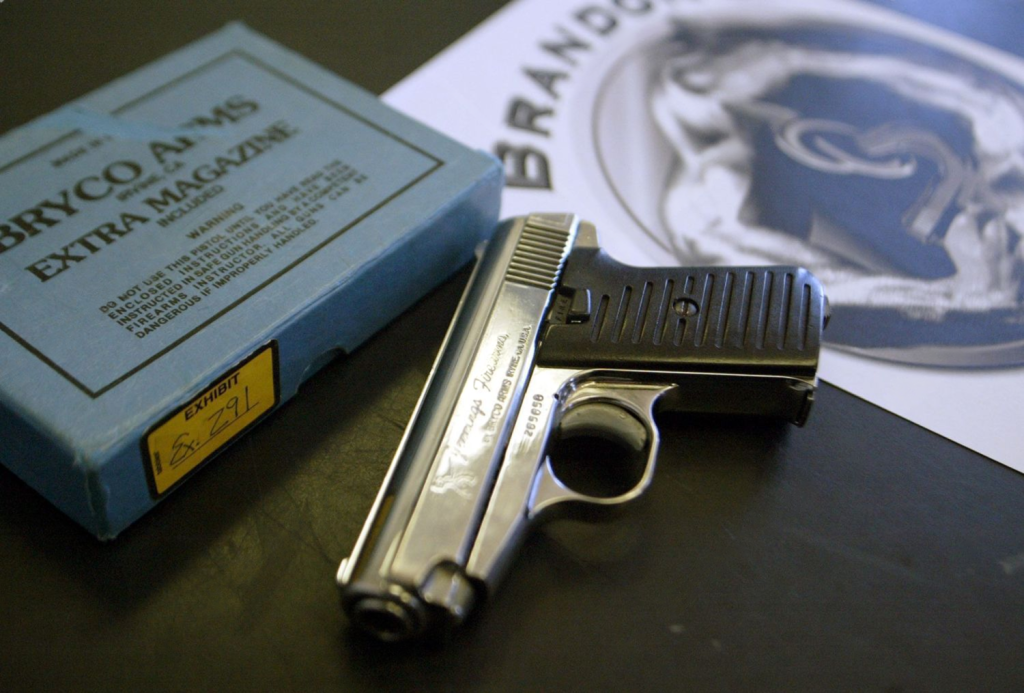

10. Bryco Arms Model 38

The Model 38 was an attempt to offer a bigger caliber take on the same budget-material playbook, which created a big-looking handgun made of zinc. Problems with feeding were frequent such as a painted feed ramp which was reported to be encouraging hollow points to hang up. With time, the weak striker springs were correlated with the light hits of the primer, making a click the most predictable aspect of the gun.

These pistols are not remembered as unpopular, but as having shortcomings that were mechanical in nature, reproducible and repeatable. The coincidence is the same weak materials, poor tolerances, controls that are unaware of the way hands actually operate, and safety systems that fail to offer the margin modern shooters expect.

Background Mainstream handgun design was evolving to less complex ignition and stacked internal protection-mechanisms (since recognized as trigger safeties and drop safeties) exactly to minimize the types of failures that had made them notorious.