It starts with a problem hiding in plain sight: America already digs up almost every critical mineral it needs for clean energy, defense, and advanced manufacturing but then throws most of it away. Elizabeth Holley, a mining engineer at the Colorado School of Mines, calls it “low-hanging fruit,” buried not in untouched ore deposits but in the tailings piles of existing mines. Her team’s new study shows that one year of U.S. mine waste contains enough lithium to power 10 million electric cars and enough manganese for 99 million. The challenge is not geology it’s engineering, economics, and political will.

1. Mapping the Hidden Resource Base

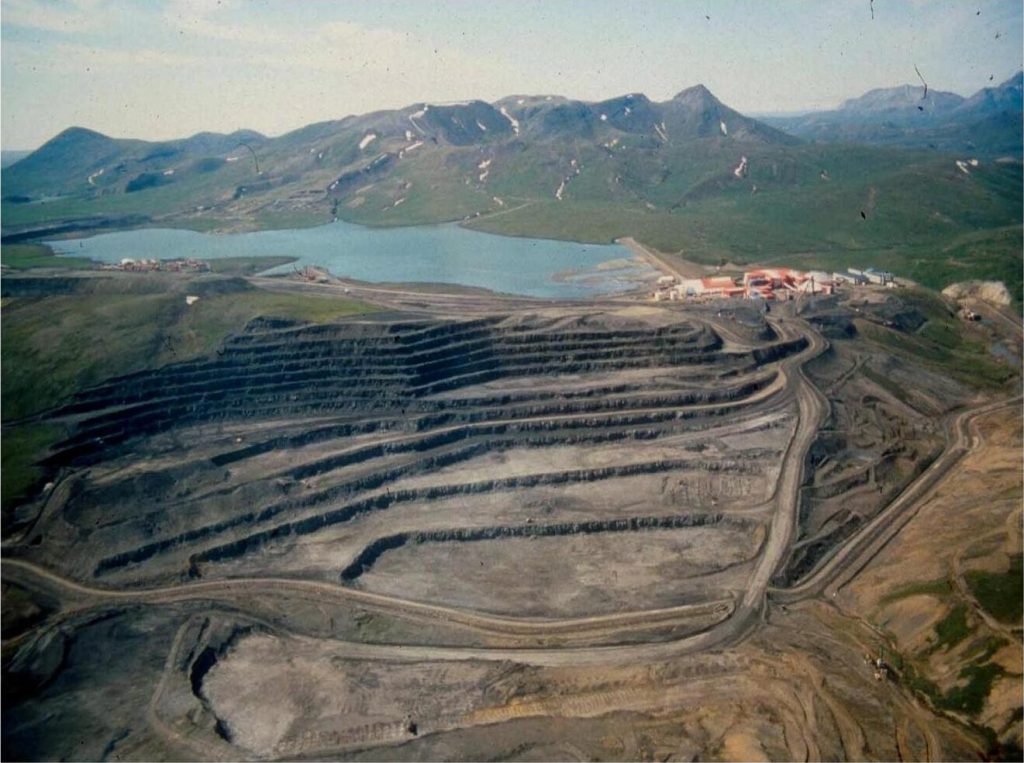

Holley’s team analyzed ore chemistry from 54 active U.S. metal mines, cross-referencing production data to create a first-of-its-kind map of critical mineral potential in mine waste. The findings reveal vast quantities of cobalt, gallium, germanium, rare earths, and other strategic metals discarded during primary commodity extraction. At Alaska’s Red Dog mine, tailings hold some of the nation’s richest germanium potential; Montana’s Stillwater and East Boulder mines could yield nickel-rich byproducts. The U.S. Geological Survey’s Earth Mapping Resources Initiative is expanding this inventory nationwide, identifying enrichment in sites such as Missouri’s Pea Ridge iron mine and Oklahoma’s Tar Creek Superfund site.

2. Engineering Routes to Recovery

The recovery of trace minerals from tailings requires separation technologies that are quite advanced. Conventional circuits are optimized for primary metals with trace elements remaining unrecovered. Hydrometallurgical methods involving acid leaching, solvent extraction, and ion exchange can dissolve and isolate rare earths, cobalt, and tellurium from complex waste matrices. Bioleaching uses microbial agents to liberate metals from sulfide minerals, with a much-reduced energy requirement associated with lower chemical risks. Molecular Recognition Technology exploits highly specific chemical interactions to obtain high-purity separations with improved selectivity over earlier methods.

3. Life-Cycle and Environmental Impacts

Tailings reprocessing can lower environmental liabilities through the removal of toxic metals and waste stabilization. Mine tailings often require perpetual monitoring because of dam failures, acid mine drainage, and heavy metal leaching. The stripping of valuable metals can make the residues more inert; in many cases, this may enable their reuse in construction materials. The weathering at legacy sites transforms minerals-germanium, for example, from sphalerite to hemimorphite-which requires specifically adapted recovery processes.

4. Geopolitical Drivers

Global supply chains for key minerals have high levels of concentration. China leads in approximately 91% of rare earth separation and 93% of permanent magnet manufacturing, commanding midstream lithium-ion battery materials with market shares above 80%. Recent Chinese export controls on rare earths, magnets, and battery inputs-some targeting products containing as little as 0.1% Chinese-origin material-have further tightened supply to defense systems, EVs, and renewable energy technologies.

5. National Security Implications

Satellites, fighter jets, radar systems, and AI data centers depend on critical minerals. The Pentagon has committed $400 million to MP Materials, the operator of the country’s only rare-earth mine, and secured a decade-long offtake agreement for its planned “10X Facility” magnet plant. Yet, until domestic processing scales, China retains leverage over U.S. defense supply chains. Mine-waste byproduct recovery could insulate national security manufacturing from geopolitical shocks.

6. Policy and Economic Incentives

The Department of Energy has launched pilot programs and announced $355 million in funding for large-scale recovery facilities including $80 million for “Mine of the Future” proving grounds. The Department of the Interior is streamlining regulations to make mine waste recovery projects eligible for federal funding. But Congress has cut key science budgets, and Holley warns that without sustained incentives, industry-operating on tight margins-will not risk capital on unproven circuits.

7. Targeted Recovery Case Studies

In the Bingham Canyon mine of Utah, substantial tellurium grains fall into tailings; at Tar Creek, zinc and germanium have moved into new mineral forms that call for novel extractive approaches. The sulfide tailings from Zn–Pb–Cu mines of Australia bear high manganese grades recoverable by successive precipitation and solvent extraction. Acid mine drainage sludge can provide high-purity rare earth oxides through post-oxidation solvent extraction, whereas tailings of silver can liberate cobalt, copper, and lead following sodium carbonate roasting and acid leaching.

8. Integration into the Circular Economy

Waste mining has a fit within the circular economy approach: securing metals from tailings, coal ash, and industrial byproducts decreases the dependence on virgin ore and speeds up supply chains. Heavy mineral sands in Georgia already yield rare earth concentrates as byproducts of titanium and zirconium mining, while kaolin tailings could be tapped for additional rare earths. Existing infrastructure shortens timelines from decades to years, enabling faster market entry for critical materials.

9. Technical Bottlenecks and Research Needs

Low concentrations, complex mineralogy, and co-dissolution of unwanted metals make recovery economics challenging. Process optimization balances selectivity with cost and environmental safety. New reagents, bio-based leaching agents, and hybrid circuits that integrate physical and chemical separation steps are in development. Systematic sampling and mineralogical characterization, supported by automated mineralogy analyzers, are crucial to modeling recoverable yields and guiding investment decisions.

Reclaiming critical minerals from mine waste could simultaneously stabilize supply chains, reduce environmental hazards, and neutralize foreign leverage over strategic sectors. The resources are already in America’s hands; the question is whether engineering innovation and policy alignment can bring them to market before the next supply shock hits.