Could one mislabeled wire really bring down a major US bridge? Investigators say yes-and the chain of engineering failures that followed reads like a textbook case in how small oversights can cascade into catastrophic infrastructure loss.

1. The Misplaced Label That Started It All

The US NTSB determined that an improperly located identification label on a signal wire during the construction of the Dali prevented the cable from fully seating in its circuit breaker terminal. During more than nine years of operation, constant vibration continued to loosen the connection. This bad contact initiated the vessel’s first blackout on 26 March 2024, knocking out propulsion, steering, bow thruster control, water pumps, and critical navigation lighting. According to NTSB Chair Jennifer Homendy, the pursuit of the culprit was “like hunting for a loose rivet on the Eiffel Tower,” considering the vessel’s miles of wiring and thousands of electrical connections.

2. Dual Blackouts and Loss of Control

The first outage lasted 58 seconds before the crew reset the breaker. However, a key flushing pump feeding fuel to the generators required manual restart-a task entailing a descent two decks in near-total darkness. Unless this restart occurred, fuel lines ran dry, leading to a second blackout just three ship lengths from the Francis Scott Key Bridge. This sequence left pilots unable to alter course in time despite immediate warnings to authorities.

3. Engineering Oversights regarding Marine Electrical Systems

The flushing pump in service was designed for maintenance, not for a continuous fuel supply, and did not have automatic restart capability. The NTSB pointed out that infrared thermal imaging, a common diagnostic used throughout maritime electrical maintenance, would have identified the overheating signature of the loose wire long before failure. However, such scans were not part of the Dali’s routine inspections. To that, senior marine engineer Barton Barnum added this was “an intermittent electrical issue failure” – thus very hard to detect without specialized tools.

4. Bridge Vulnerability and Structural Risk

Calculations showed the collision force was nearly five times the pier’s structural capacity. Investigators showed the Key Bridge had 30 times the acceptable collapse risk for critical bridges if struck according to American Association of State Highway and Transportation Officials guidance. No vulnerability assessment had been performed by MDTA since the bridge opened in 1977 even though discussions about pier protection had been ongoing for two decades.

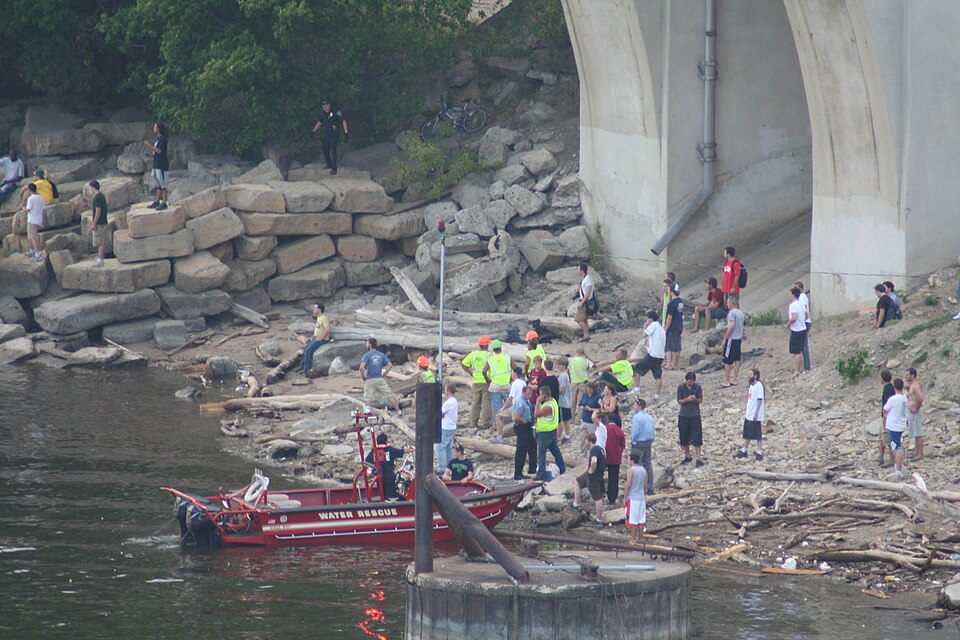

5. Emergency Response and Lost Seconds

The MDTA police stopped vehicle traffic across the bridge 48 seconds before the impact, likely averting an even higher death toll. However, construction workers on the bridge were not warned in time; using engineer estimates, they would have had 1 minute and 29 seconds to clear the steel structure had the warnings been issued simultaneously. Six workers died when the span fell; one survived with injury.

6. Recommendations for Maritime Safety

The NTSB issued 17 safety recommendations calling on shipbuilders to use proper wire-label installation methods, operators to incorporate redundant fuel supply systems, and bridge owners to conduct vulnerability assessments. Board member Michael Graham compared the needed changes to aviation’s rigorous safety culture, saying, “Many of these issues… could have been identified, addressed and either mitigated or eliminated.”

7. Francis Scott Key Bridge Reconstruction

The new MDTA design has a 1,665 foot main span with pier protection fenders the size of more than one football field, designed to absorb the impact of modern ultra-large container vessels. Estimates have risen to between $4.3 and $5.2 billion-more than twice early estimates-and completion has been pushed back to late 2030. Escalation drivers include rising material costs, larger pier protection, and greater span height. The majority of the cost is being provided under federal emergency relief, supplemented by insurance proceeds and legal claims against the Dali’s owner.

8. Industry Accountability and Continuing Legal Action

Grace Ocean Limited, the vessel’s owner, has filed a lawsuit against Hyundai Heavy Industries for defective design. Hyundai says the wire was properly secured at delivery and that periodic checks should have uncovered loosening over time. The NTSB faulted Synergy Marine Group, the operating company, for not revising policies about fuel pump usage despite having unrestricted access for 20 months to the results of the investigations.

The Dali’s crash, besides stopping operations at one of America’s busiest ports for months, brought to light systemic gaps both in the realm of maritime electrical safety and bridge impact resilience. The findings of the NTSB underline how a single mislabeled wire, which was overlooked for years, can trigger a chain reaction that results in the destruction of a critical transport link.