But what if the next leap in aerospace wasn’t about bigger missiles, but cleaner, faster aircraft? In a defense landscape dominated by speed and range, a reusable hydrogen-fueled hypersonic jet may sound like science fiction-but Australia’s Hypersonix Launch Systems is turning it into a funded reality. Backed with $46 million from both sovereign and global investors, the Brisbane-based company is building a platform that could redefine both military and commercial high-speed flight.

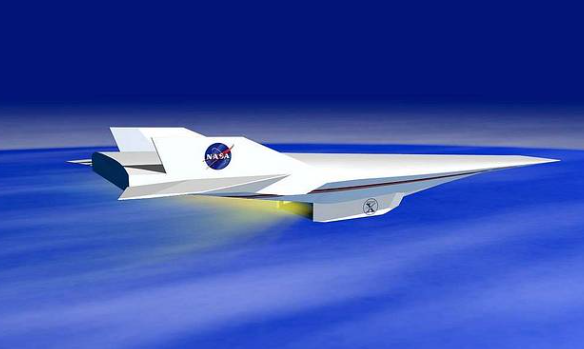

The pursuit of hypersonic capability has long been a three-way sprint between the US, China, and Russia. However, Australia’s academic community has quietly led the world in scramjet research. Today, Hypersonix’s SPARTAN engine-a fully 3-D-printed, air-breathing hydrogen scramjet-promises Mach 12 performance without carbon emissions. This listicle explores the key breakthroughs and strategic moves behind the project, from material science right through to manufacturing innovations, and why they matter for the future of aerospace.

1. Strategic $46 Million Series A Funding

Hypersonix just raised $46 million in a Series A round, and this marks a turning point for hypersonic ambitions in Australia. It is an investment that has been led by UK-based High Tor Capital and supported by Saab, RKKVC, and other local giants such as the National Reconstruction Fund Corporation and Queensland Investment Corporation. This investment is considered the first-ever defense investment by the NRFC. According to NRFC CEO David Gall, “Defense is one of our priority areas. huge potential in backing Australian companies and innovations that build sovereign capability.” This would not only accelerate Hypersonix’s development but also be a vote of confidence from those key international players in clean, reusable aerospace systems.

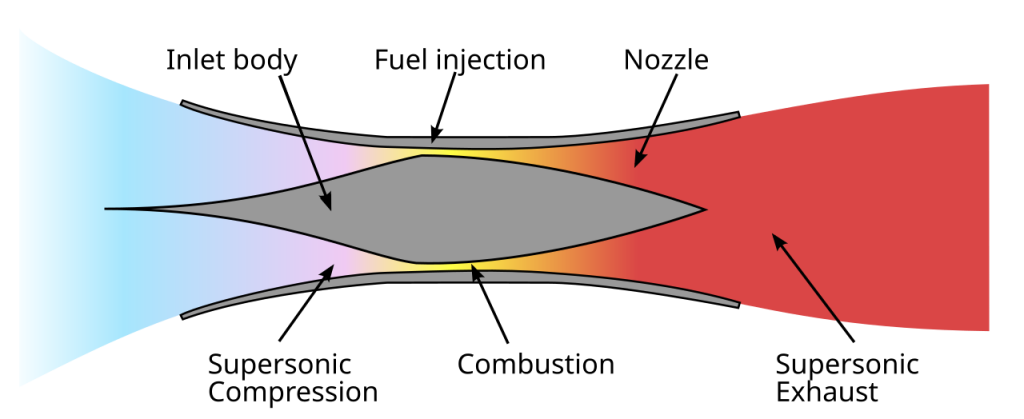

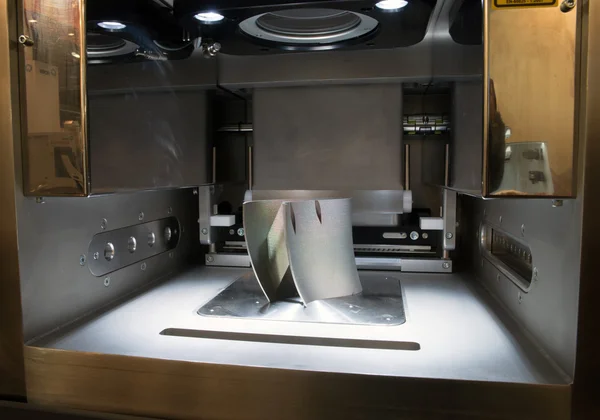

2. SPARTAN: A 3D-Printed Hydrogen Scramjet

At the heart of Hypersonix’s aircraft is the SPARTAN scramjet-an air-breathing, fully 3D-printed engine with no moving parts. Unlike kerosene-fueled scramjets, SPARTAN burns hydrogen, a zero-carbon-emissions fuel that will enable reusable, low-maintenance hypersonic flight. “It’s a breakthrough in reusable hypersonic flight,” says co-founder Dr Michael Smart. Its design uses additive manufacturing to realize geometric complexity and weight reduction with no compromise in performance, echoing such advances as full-scale scramjet prototypes at Purdue University.

3. NASA and Pentagon-Backed DART AE Flight

Proceeds from the funding will go towards supporting the DART AE test flight under the US Department of Defense’s HyCAT program, led by the Defense Innovation Unit. The 3.5-meter-long vehicle will lift off aboard Rocket Lab’s HASTE booster from NASA’s Wallops Flight Facility. DIU program manager Maj. Ryan Weed characterized the effort as a “paradigm shift, viewing the hypersonic realm as a place for aircraft, not just missiles and weapons.” If successful, this will be the world’s first sustained hypersonic flight powered by green hydrogen.

4. VISR: Multi-Engine Hypersonic ISR Platform

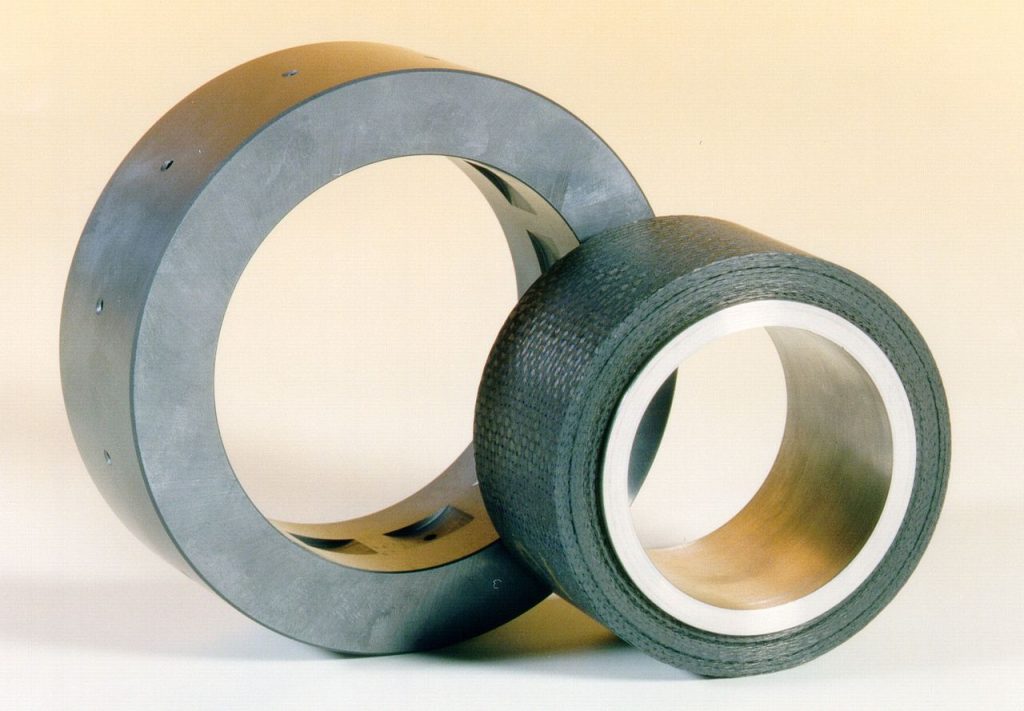

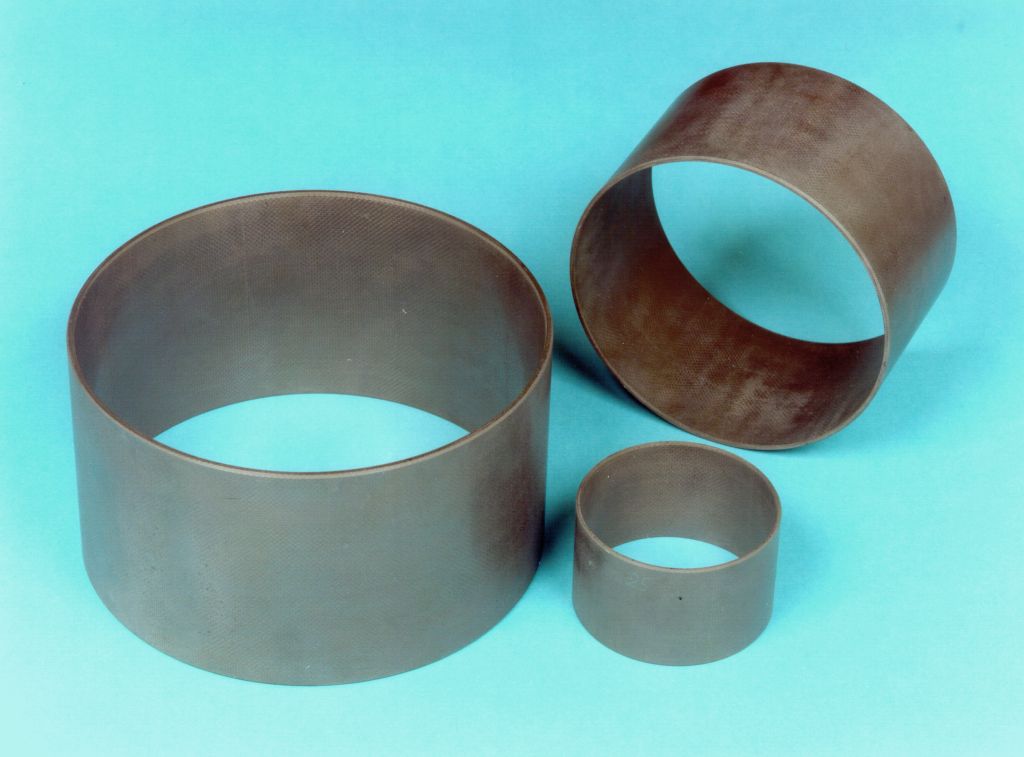

Beyond DART AE, Hypersonix has been working on an 8-meter-long reusable aircraft called VISR, powered by four SPARTAN engines. Built from high-temperature ceramic composites, VISR is for use in intelligence, surveillance and reconnaissance, rapid payload delivery, and the testing of space systems. This reflects state-of-the-art research into Ultra High Temperature Ceramic Matrix Composites that can handle over 2,000 degrees in strongly oxidizing hypersonic conditions.

5. Sovereign Capability and Allied Integration

Chairman Arthur Sinodinos declared, “Australia is stepping up to develop sovereign capabilities that matter.” The aircraft’s potential will go beyond national defense since it will give allied nations a reusable platform for hypersonic and counter-hypersonic missions. QIC Ventures Partner Nicholas Guest commented on its “unparalleled combination of speed, sustainability, and cost advantage.” The aircraft is stated to be a strategic asset for the partners in their need for high-cadence flight testing.

6. HyCAT Program-Mandated High-Cadence Testing

HyCAT addresses an important need in the hypersonic community: affordable repeatable test flights. DART AE will provide DIU with speeds over Mach 5, maneuverable non-ballistic profiles, and at least three minutes of sustained flight. The platform’s modular payload bay allows for rapid integration. Kratos Defense will provide solid rocket motors in support of booster compatibility. This has the potential to cut development cycles for hypersonic systems by an order of magnitude.

7. Additive Manufacturing for Hypersonic Engines

Hypersonix’s manufacturing approach is part of broader industry trends, from Velo3D’s LPBF 3D-printed ramjets to Purdue’s vertically integrated scramjet prototyping. Each of the aforementioned techniques reduces part counts, improves structural integrity, and enables rapid iteration. Where tolerances are extreme as in hypersonics, additive manufacturing is the fastest way from design to flight-ready hardware.

8. Materials for Extreme Aerothermal Loads

Hypersonic vehicles experience orders-of-magnitude larger heat fluxes than the most concentrated solar radiation, with thermal gradients ranging from -170°C to 3,000°C over centimeters. C/SiC and UHTCMC are in development for tolerance against repeated exposure to high-speed ionized gas flows. Material science is a rate-limiting factor for reusable hypersonic platforms now, as exemplified by VISR’s ceramic composites.

9. From Academic Research to Operational Systems

The journey of Dr Smart from research at NASA to leading hypersonic propulsion at the University of Queensland underlines Australia’s long-standing leadership in the field. Hypersonix bridges academic theory and operational capability, with the aim of making hypersonic flight not just faster but more frequent and more affordable. As Smart put it, “The ability to fly often and affordably is the key to unlocking hypersonics for both defense and commercial use.”

Hypersonix’s Mach 12 hydrogen-fueled aircraft is more than a propulsion milestone; it’s a meeting point of sovereign investment, additive manufacturing, and advanced materials research. In marrying sustainability with extreme performance, the project may reimagine how hypersonic systems are created, tested, and fielded, positioning Australia and its allies at the leading edge of a cleaner and faster aerospace future.