The question of who really builds America’s most advanced fighter jet and how many are in service gets to the very core of modern military aviation at a crossroads of technologies, industrial scale, and strategic alliances. The F-35 Lightning II program goes beyond manufacturing a stealth aircraft to sustaining a global defense network, managing a vast supply chain, and fielding a fighter that meets diverse operational needs across multiple services.

Now helmed by Lockheed Martin and a deeply interwoven set of international partners, the Joint Strike Fighter program is the biggest and most complex defense procurement in history. That makes the story of the F-35 as much about manufacturing innovation and geopolitical cooperation as it is about combat capability. This listicle parses key facts-who makes the jet, how many fly under the US flag-to frame up a clear view of scale, variants, and future trajectory.

1. Lockheed Martin leads a global production network

The prime contractor for the F-35 Lightning II is Lockheed Martin, selected as the winner of the Joint Strike Fighter competition in 2001 with its X-35 concept against Boeing’s X-32. Production is distributed internationally, though Fort Worth, Texas, remains the central assembly hub. Italy’s Cameri facility, operated with Leonardo, builds and services European F-35s, while Japan’s Mitsubishi Heavy Industries assembles jets in Nagoya. This global approach integrates more than 1,650 suppliers from nations including the UK, Australia, and the Netherlands, making the F-35 truly multinational.

2. Specialized Component Supply Chain

Construction of the F-35 depends on a broad base of suppliers that provide critical systems. Pratt & Whitney builds the F135 engine, Raytheon supplies avionics and munitions, and Collins Aerospace designs the advanced pilot helmet. Foreign contributions come from sources such as Martin-Baker for ejection seats in the UK, Alenia Aermacchi for wings in Italy, IHI Corp for engine parts in Japan, and Fokker for landing gear doors in the Netherlands. Machining challenges such as titanium for aerostructures have driven new machining developments such as Starrag’s Big Titanium Profiler used in UK and Australian facilities.

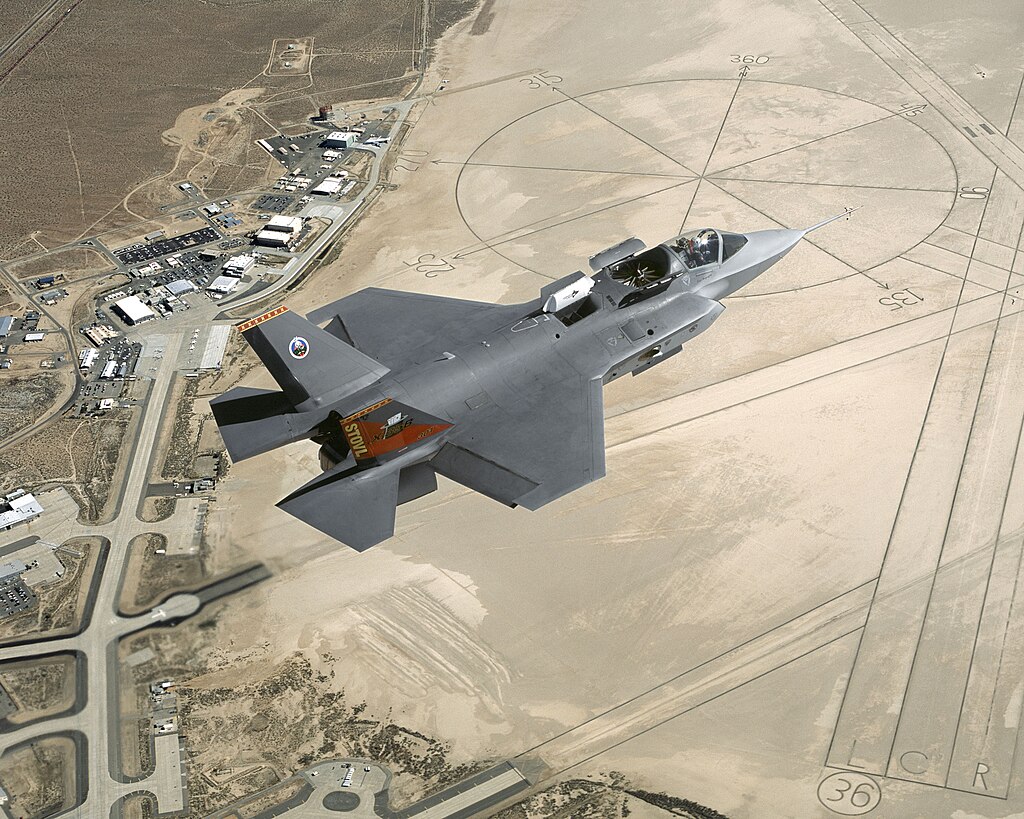

3. Three Clearly Differentiated Variants for Varied Missions

The principal variants that the program fields are the conventionally taking off and landing F-35A, the STOVL-capable F-35B, and the carrier-suitable F-35C. The A variant provides the highest agility at 9G and integrates an internal gun, the B exchanges range for STOVL flexibility, and the C’s larger wings enhance both carrier operations and fuel capacity. Each is optimized for particular service needs, with between 27% and 40% parts commonality, underscoring the challenge of maintaining the fleet.

4. Current US Fleet Strength

At present, the United States operates a total of 601 F-35s across the services. The Air Force currently operates 246 F-35As in combat units and 139 in training units, having ordered 1,350 total. The Marine Corps flies 122 operational F-35Bs and Cs, plus 38 training, with 164 on order. The Navy has 41 operational F-35Cs, with 15 training and 193 on order. In all, the US has committed to 1,707 aircraft, making the F-35 one of the most numerous fighter types in its inventory.

5. International Partnerships and Export Reach

Seven US allies are cost-sharing partners, and many others have placed orders. Italy and Japan host final assembly lines; the UK provides significant subsystems. From Australia to Norway, nations integrate the F-35 into their air forces, often configuring it to local requirements. Unique sensors, electronic countermeasures, and planned conformal fuel tanks on Israel’s F-35I “Adir” variant illustrate how the platform adapts to different strategic contexts.

6. Block 4 Modernization and Technical Refresh 3

The Block 4 upgrades the Joint Program Office is pursuing will further integrate advanced sensors, electronic warfare systems, and long-range precision weapons. TR-3 will provide the computing power to enable those enhancements but itself has suffered from hardware integration delays. The GAO reported that some Block 4 capabilities would not arrive until the 2030s, as part of the “Reimagined Block 4” that prioritizes must-have features.

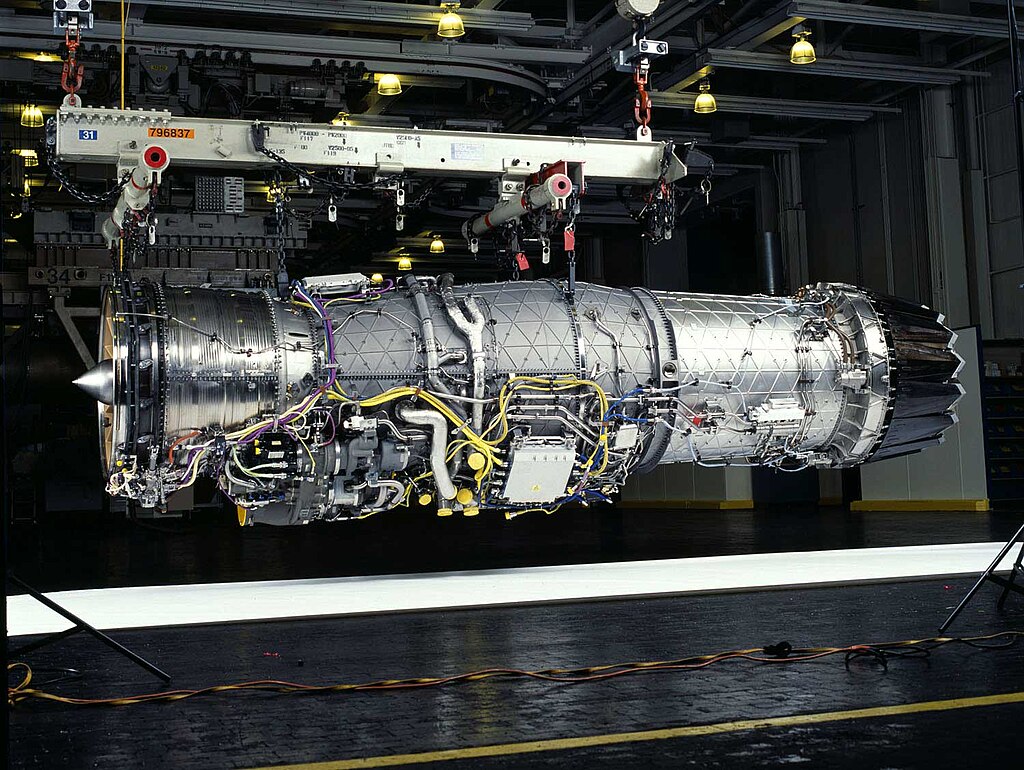

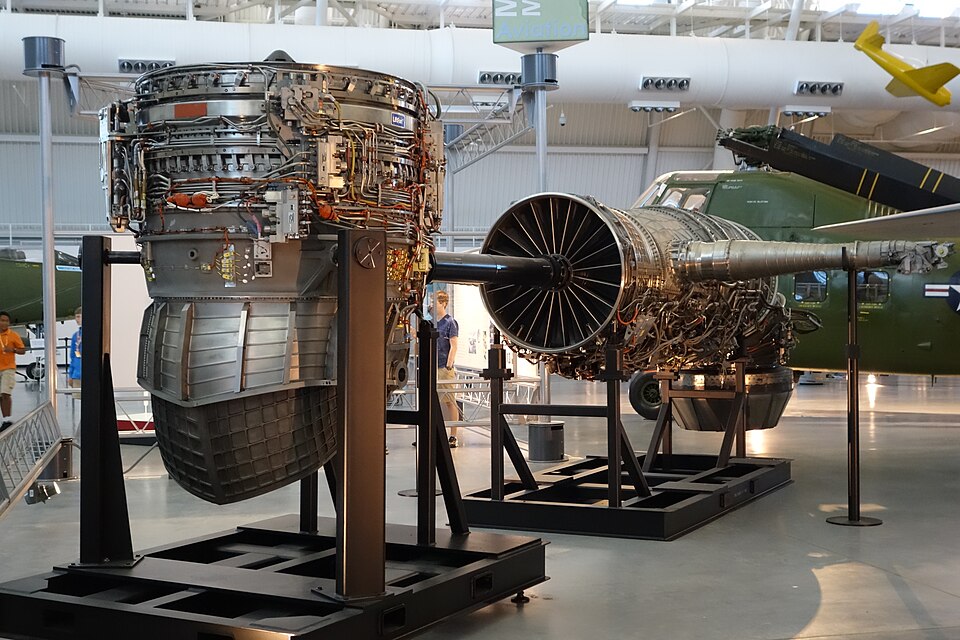

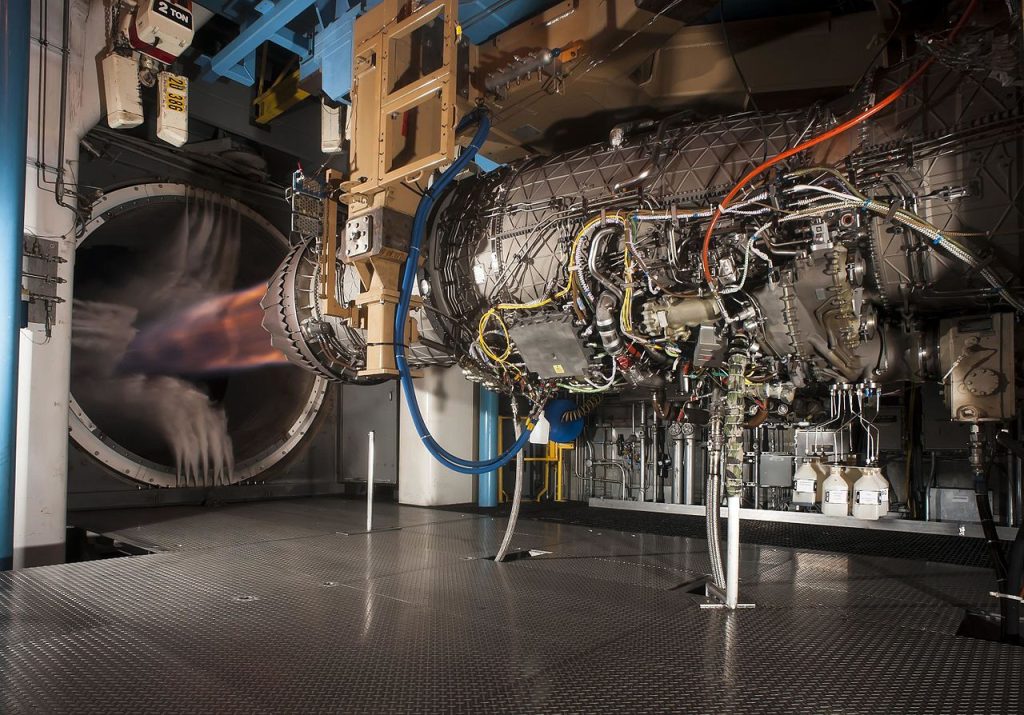

7. Engine Core Upgrade for Future Capability

The Pratt & Whitney F135 engine already provides more than 40,000 pounds of thrust and is receiving an Engine Core Upgrade in support of Block 4’s greater power and cooling requirements. The cost estimate is $527 million in FY2025, with the intent of increasing engine life to 2,000 hours before overhaul and mitigating decreased vertical lift in the F-35B due to weight growth. Development costs for associated upgrades in thermal management could be upwards of $4.5 billion.

8. Sustainment Challenges and Readiness Rates

According to GAO, sustainment costs for the F-35 have grown to $1.6 trillion in part because of extending service life out to 2088. In 2023, mission capable rates fell short of targets: 51.9% in the Air Force’s fleet of F-35As, the Marine Corps fleet of F-35Bs at 59.7%, and the Navy’s fleet of F-35Cs at 61.9%. Among the contributing factors are dependencies on contractors, spares supply shortfalls, and incomplete technical data packages. Improving the efficiency of maintenance involves transitioning from ALIS to the cloud-based ODIN, among other things.

9. Production Lots and Procurement Trends

Seventeen production lots have been negotiated, the most recent of which was the $30 billion Lot 15 and Lot 16 deal for 398 aircraft plus an option for Lot 17. Prices for Lots 18 and 19, some 300 aircraft, may go up because of rising labor, material, and energy costs. The block-buy strategy for Lots 20–24 could save up to $1.1 billion as the program juggles procurement rates with modernization funding under budget caps. More than just a fighter, the F-35 Lightning II is a mainstay for US and allied air power, a symbol of industrial collaboration, and a test case in managing complex multinational defense programs. The future of the aircraft will be determined by a delicate balance between production efficiency, sustainment affordability, and technological superiority as its fleet continues to grow and its capabilities evolve through modernization. To any keen observer of all things defense, the F-35 remains a very real example of where cutting-edge engineering meets strategic necessity.