“Electric cars are the future,” say some, but the future has its own attendant problems, particularly for something as basic as tires. As electric cars (EVs) become increasingly trendy, motorists are finding that the technology below their feet is changing nearly as rapidly as the batteries below the bumper. But one recurring problem overshadows them all: EVs seem to consume their tires with a voracity that even veteran motorists find surprising.

This rapid tire degradation is more than a nuisance; it’s an engineering, economic, and environmental mystery. From the singular stresses of immediate torque to the chemistry of contemporary rubber, identifying the underlying cause and solution is vital for those looking at an EV or already dealing with the realities of electric mobility. Here, the most compelling arguments behind quick tire degradation on EVs are examined, in conjunction with recent innovations and mitigation strategies to address the issue.

1. The Heavyweight Challenge: EVs and Their Big Batteries

Some of the biggest contributors to the speed at which tires wear out in electric vehicles are their size. Unlike traditional gasoline cars, EVs have huge battery packs that weigh in excess of 1,000 pounds with some models weighing close to 3,000 pounds, close to the weight of a whole compact car. This extra weight puts far greater pressure on tires, raising friction on the road and accelerating tread wear. Increasing a midsize vehicle by 1,000 pounds can add around 20% more tire wear, said Emissions Analytics. The heavier the vehicle, the more often owners will need to replace tires, affecting both maintenance costs and environmental targets.

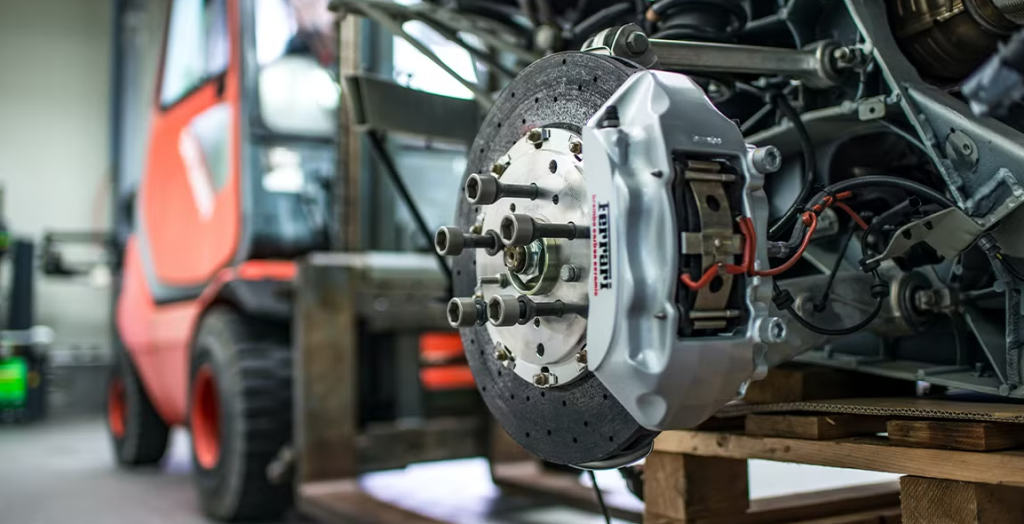

2. Instant Torque: The Double-Edged Sword of Electric Performance

Electric cars are famous for their on-demand torque output, a characteristic that offers out-and-out acceleration from a dead stop. Internal combustion engines, in contrast, need the accumulation of revolutions before they can output power. EVs, however, transfer energy to wheels directly with minimal lag. This instant force is thrilling but adds to the load on tire rubber, particularly in hard acceleration and hard starts. As Michelin explains, the interplay between instant torque and weight of the vehicle creates an EV-specific wear profile, necessitating tire compounds and constructions able to sustain such stresses over a period.

3. The Contribution of Regenerative Braking and Light Coasting

Aside from acceleration, EVs also suffer more tire wear because of their braking system. Regenerative braking, which saves energy during braking, results in force being nearly constantly applied to the wheels either to move the vehicle forward or to brake. According to industry analysis by Dale Harrigle, Bridgestone Americas’ chief engineer, “There’s very little coasting that occurs in an electric vehicle, and that’s part of the reason why the wear life is reduced.” This almost-constant force application reduces the life of tires by 20–30% relative to those of gasoline-fueled cars.

4. Dedicated Tire Compounds: Striking a Balance Between Durability, Efficiency, and Safety

To address the specific requirements of EVs, tire makers are formulating new compounds and tread patterns. Contemporary EV tires feature advanced rubber compounds and reinforcing elements like silica, which minimise rolling resistance and enhance wet grip. Technologies such as Sailun’s EcoPoint 3 and Bridgestone’s PeakLife polymer are created to increase both energy efficiency and longevity, all while preserving the safety-critical grip needed for high-torque applications and beyond. But these technologies typically come with trade-offs, where some tires sacrifice range and comfort for ultimate tread life.

5. The Magic Triangle: Rolling Resistance, Wear, and Wet Grip

Tire technologists call the interaction among rolling resistance, wear resistance, and wet grip the “magic triangle.” Enhancing one of these can frequently come at the expense of another. Reducing rolling resistance, for instance, increases efficiency and range but tends to decrease wet grip, which is critical to safety. Recent advances, including the application of precipitated silica and coupling agents, have enabled manufacturers to reach lower rolling resistance without incurring a loss of wear resistance or wet traction. According to Stephen Moller of Evonik Industries, “The silica-silane network is able to deal with a lot more stresses because it’s not just filling the rubber, it’s actually interacting with the rubber.”

6. Noise Matters: The Quiet Revolution Inside the Cabin

With the quiet operation of electric motors, road and tire noise become much more prominent in EV interiors. Tire manufacturers are pushing back with technologies such as open-cell polyurethane foam inserts and sophisticated tread patterns that absorb vibrations and minimize noise. Goodyear’s Sound Comfort technology, for example, has up to 50% less cabin noise than traditional tires. This emphasis on acoustic comfort is transforming tire design, as the lack of engine noise lays bare every detail of tire-road interaction.

7. Environmental Impact: Tire Wear as a Source of Pollution

Although EVs cut tailpipe emissions, their tires are a new source of environmental concern. Tire and road-wear particles are a source of microplastic pollution in air, water, and soil. Emissions Analytics estimates that one car loses nearly nine pounds of tire material annually, and globally, that comes to 6 million metric tons per year. Chemicals such as 6PPD, an additive employed to forestall rubber cracking, can be broken down into harmful chemicals like 6PPD-quinone, which has been associated with aquatic organisms’ deaths and is detected in human urine samples across the world. As regulators start to tackle these challenges, tire makers are pushed to create less harmful, more secure alternatives.

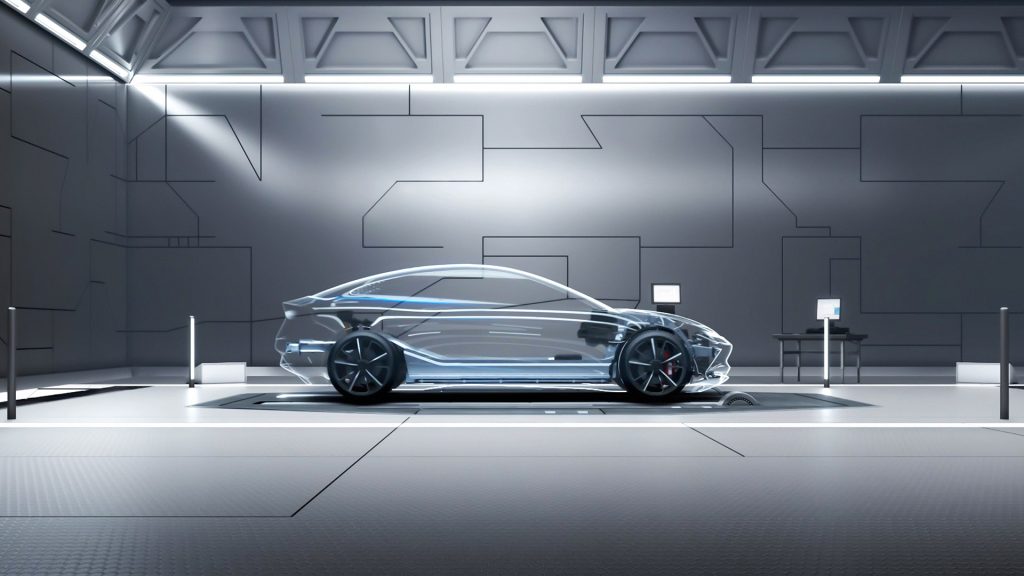

8. Testing and Technology: How EV Tires Are Evaluated

Testing electric vehicle tires necessitates new standards to accommodate increased loads, greater torque, and distinctive sound profiles. Facilities like the Smithers Tire and Wheel Test Center use advanced machinery to simulate the stresses EV tires endure, from rolling resistance at various temperatures to high-load snow traction. “Rolling resistance and F&M testing for an EV tire will be done at a higher load to mimic the huge weight of an EV battery,” says Cliff Hodges, technical director at Smithers. This aggressive testing assures that new tire designs pass both regulatory requirements and changing expectations of EV drivers in the marketplace.

9. What Drivers Can Do: Maintenance and Smarter Choices

Although tire technology continues to advance, vehicle operators continue to contribute a great deal to extending the life of tires. Periodic checkups on tire pressure, tire rotation and alignment, and controlled acceleration can all help extend tread life. The use of EV-specific tires with advanced tread compound and strengthened carcasses is also advised. As Michelin notes, “pressing the pedal to the metal too frequently can tire out your tires more quickly, so it is better to savor that EV fun factor in moderation” for longevity.

The fast deterioration of EV tires is a many-sided problem, influenced by physics, chemistry, and people’s behavior. As producers are working feverishly to develop more durable, quieter, and safer tires, drivers’ and policymakers’ decisions will also decide how eco-friendly and affordable electric mobility turns out to be. In this new reality, knowledge is as important as the rubber hitting the road.