Is it really innovation if you’re just painting over structural cracks? That’s the question echoing through defense circles as Lockheed Martin’s rumored F-55 a supposed twin-engine evolution of the F-35 draws sharp insider rebuke and triggers a broader debate about the future of American air dominance.

1. The Structural Limits of the F-35: “Baked-In” Compromises

The F-35 Lightning II was conceived on a grand vision: designing one, stealthy airframe that would be capable of serving the Air Force, Navy, and Marine Corps with minimal changes. But as one Western defense industry official described it, “The F-35 is a broken design too many of its basic problems are baked into the airframe.” This is not just rhetoric. The single engine, small wing area, and closely integrated fuselage of the F-35 were all driven by the necessity to fit vertical takeoff for the F-35B and carrier operation for the F-35C. Those design decisions have placed irreversible sacrifices in lift, range, and maintainability, which, critics say, “are limits you can’t engineer your way out of.”

2. The F-55: A Marketing Mirage or Engineering Reality?

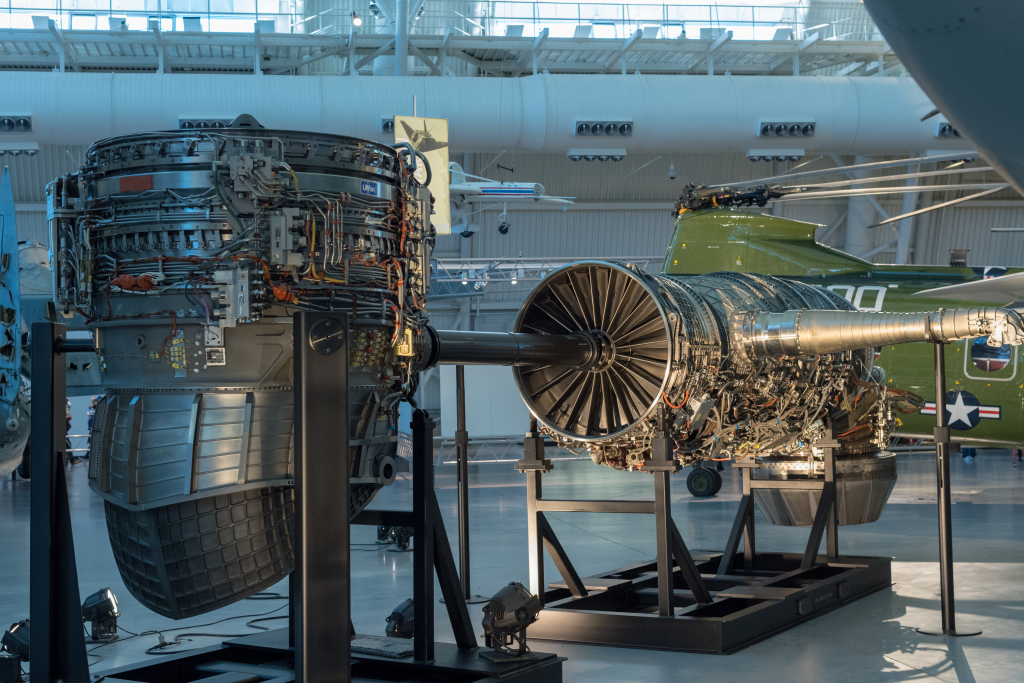

President Trump’s May 2025 Doha promise of a “super upgrade on the F-35” with two engines elicited instant ridicule from technical analysts. “A two engine version of the F-35 would essentially be a total redesign,” declared former Air Force Secretary Frank Kendall, continuing, “It’s an option that was never offered and that we never looked at.” Aerospace analyst Richard Aboulafia was even more direct: “It’s not possible. It’s referred to, ‘Pick up the windscreen and install a new aircraft.'” F-35’s airframe is centered on its sole Pratt & Whitney F135 engine, which produces 43,000 pounds of thrust. Retired USAF Lt. Col. Eric Gunzinger, who was once an F-35 program manager, clarified, “To add two engines to it would be a total redesign of not just the hardware and the airframe, but also the software.” The outcome? “You’re not building a variant you’re building an entirely new aircraft.” Redesigning the F-35 for twin engines is essentially building a whole new aircraft.

3. Engineering Hurdles: From Stealth to Structure

Adding a second engine is not as simple as doubling the powerplant. The airframe would need to be enlarged and structurally reinforced to handle the increased thrust and mass. This would require an entire redesign of the fuselage, wings, tail, and stealth fairings. J.J. Gertler, a senior analyst with the Teal Group, said, “The new airframe doesn’t just have to be larger, it has to be more powerful to manage double the thrust.” Two engines implies a significantly higher top speed, and so you may have to redesign the wing and tail and definitely the intakes. Redesigning the engine arrangement while keeping the F-35’s low radar cross-section would mean having to rerun all the calculations and shaping in order to actually preserve the amount of stealth that it possesses. As the Center for a New American Security’s Stacie Pettyjohn noted, “Adding a big change, like an engine, is gonna have implications that run through the whole airframe.”

4. F-35 Performance and Cost Realities

In spite of its sophisticated avionics and stealth capabilities, the F-35 has drawn repeated criticism for its 670-nautical-mile combat radius and engine unreliability. The range limitation is a byproduct of its multi-mission, compromise-based design. As Bryan Clark of the Hudson Institute observed, “The F-35’s design issues lie in its genesis more than its implementation.”

The F-35 maintenance cost of $31,000 per flight hour still is high compared to 4.5-generation fighters, though economies of scale will bring this down as production increases. But chronic engine problems, such as “harmonic resonance” crashes, have pushed low rates of aircraft availability, with some squadrons indicating that fewer than half their F-35s are mission-capable at any particular time The F-35 Range Problem That Won’t Go Away.

5. F-22 Revival: A Cheaper, Faster Alternative?

With the staggering cost and engineering risk of the F-55, there are some insiders who call for re-opening the F-22 Raptor production line. “Reopening the F-22 line and modernizing it would be smarter, less expensive, and quicker,” the industry source countered, citing the Raptor’s unchallenged air superiority and dual-engine design as reasons for it to serve as a stronger platform for future upgrade. A 2017 Air Force analysis pegged the cost of producing 194 new F-22s at around $50 billion, with unit costs falling to as low as $206 million per plane near the end of the production line. The F-22 performance remains intimidating: top speed Mach 2.25, 70,000 pounds of thrust, and radar cross-section a mere 0.0001 square meters a thousand times less than Russia’s Su-57 How to build a hybrid F-35/F-22 fighter.

6. NGAD and the Sixth-Generation Leap

As the F-55 controversy continues to rage, the Pentagon’s Next Generation Air Dominance (NGAD) program is working stealthily to redefine air combat in the future. NGAD is more than a new fighter, but rather a “family of systems” merging manned and unmanned platforms, cutting-edge stealth, and adaptive propulsion. General James Slife, USAF vice chief of staff, emphasized, “We’re going back and starting at the beginning with what is the thing we’re trying to do.” The NGAD fighter is expected to cost as much as $300 million per aircraft and will feature technologies such as variable-cycle engines, open architecture for rapid upgrades, and seamless integration with collaborative combat aircraft NGAD programme development details.

7. Budgetary Pressures and Procurement Dilemmas

Lockheed Martin’s recent public earnings releases highlight the increasing pressure: net income fell to $342 million in Q2 2025 from $1.6 billion during the same period a year ago, with negative free cash flow of $150 million. Lockheed Martin is under the double burden of protecting the F-35’s heritage and bidding for future NGAD contracts. As that one analyst succinctly put it, “This is what happens when you prioritize sales over engineering.” Boeing took that route in the commercial sector. Lockheed took it in defence, and the F-35 is the result. The Pentagon, on the other hand, is well aware that each dollar invested in F-22 or F-55 reboots could potentially come out of next-generation development.

Ultimately, the F-55 proposal is seen by many as a political maneuver rather than a genuine leap in capability. As the industry insider warned, “What we’re seeing now is not innovation. It’s damage control.” For defense professionals and aviation analysts, the lesson is clear: engineering fundamentals cannot be papered over by marketing or procurement cycles. The path to true air dominance will demand hard choices, not just bold headlines.