The reason why polymer-framed pistols are prevalent in modern holsters is that they are less weighty, well resistant to corrosion, and they have been tested to last long when subjected to intense use. On long-running frame-material arguments, most shooters tend to award polymer, however, in the consideration of weight and corrosion resistance, only to admit that the shootability is generally inclined towards steel.

But handguns made of steel do not die away. Competition On the range, during the process of making parts fit by hand in workshops, steel continues to demonstrate benefits unavailable to a spec sheet. These are the practical features that leave steel on the table, despite a polymer-first world.

1. Gravity serving as an integral recoil control

The additional mass of a steel frame lessens the amount of energy that the shooter experiences as a push-off. This is of greatest concern with faster and higher pressure cartridges and longer practice periods when fatigue manifests as slower splits and inferior hits. Its advantage is easy: the gun recovers between the shots more quickly, and the sight picture is restored more predictably.

2. Reduced center of mass that allows the muzzle to remain down

Balance is as much later to change the nature of recoil as crude weight. One thing that may be noticed is polymer guns may be perceived as top heavy as more of the weight is concentrated in the slide and barrel and this makes the muzzle lighter to recoil with. Among the technical reasons cited is how the center of gravity of polymer guns increases much more dramatically as the magazine lightens during a string, resulting in a snappiness of the final rounds more than the initial.

3. Even panning, even when sliding to frame, and it pays off

Properly done steel pistols are capable of operating with a close, consistent slide-to-frame fit that seems to be on rails. That consistency is more likely to manifest itself as a more consistent lockup and a more consistent cycling impulse which many shooters perceive as “easy to call shots” particularly as pace rises.

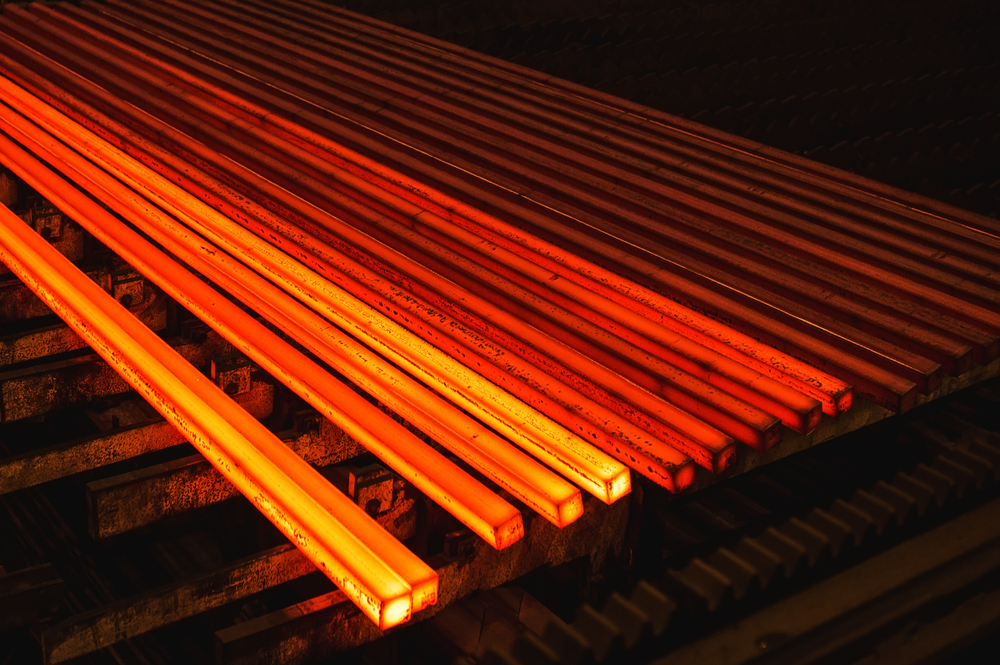

4. High-round-count tolerance to heat

Steel can undergo repetition heating and cooling without as much material concerns regarding polymers. Steel frames preserve their feel and rigidity during long match days, when the gun is warmed, and during prolonged practice strings, when the shooter is already overstrained whenever the grip and cadence are involved.

5. A frame that is welcoming, fitting, and repairing

Traditional gunsmithing can use steel and it is the most friendly frame material. In the case of metal core structure, trigger work, refitting, refinishing, and correcting wear surfaces are usually easier. Polymer frames are also very strong but they frequently depend on molded geometry and embedded items that are not meant to match to be handled in the same type of hand-fitting culture.

6. Ergonomics that is aggressively textured and not lost

Steel frames also sustain aggressive traction solutions, such as checkering, machining and add-on components without the use of flexible surfaces. This is intentionally reduced to inertial grip in modern steel-frame designs; one recent example cites increased texturing on a 9mm steel- frame that is supposed to remain locked-in at lower velocity.

7. Belief in a sound recoil impulse

Shooters explain that steel guns typically track flatter and that this gives them a sense of being more planted as opposed to being heavier. The mass, balance, and rigidity produce that impression: the gun resists the hands less, the recoil effect is not so sharp, and minor errors of technique are less severe. It does not happen to be magic simply physics and ergonomics at work.

8. The history of successful steel platforms

The shapes and forms of the modern-day pistols are still shaped and fired using iconic designs constructed with steel frames. The 1911, Browning Hi-Power, and CZ-75 families are still points of reference due to the fact that their steel construction provided support to the original geometry, triggers, and handling characteristics. And those archaic patterns are being re-emerged in the modern competition and fan culture not without a purpose.

9. Great wear trends and high round-count longevity

Any frame material will wear out, although steel is prone to do it in ways that are easier to test and repair. Conversely, pin holes, embedded rail and environmental aging are common topics of discussion in long-term discussions of polymer longevity. A frequently reiterated objection is that, repeated heating and cooling may hasten the degradation of polymer over decades, although in actual service life, maintenance and use history may dictate service life than an individual material property.

10. The sort of finish which has the power to grow old, and not to wear out

Steel acquires an honest wear, edges are polished, bluing is thinned, and point of contact narrates without always impairing operation. To several owners, that perceptible past is an element of the attraction since it combines beauty with mechanical self-assurance. Polymer is also wearable, although it never provides the patina effect collectors and longtime shooters place in steel.

The steel-framed pistols do not constitute a denial of polymer, but serve another category of priorities. Polymer is still the leader in low weight, corrosive resistance and convenience in everyday life. Steel continues to be preferred where recoil control, balance, heat capacity, and physical tunability is significant to bear the added pounds.