Any discussion of the best Army handgun is likely to fall into caliber and subjectivity. Power is more quantifiable. It manifests itself in the way the Army formulates requirements, in the way it trains the mixed experience of people, in the way the armorers maintain a piston running over decades of storage, rebuilding and re-issuing.

Out of the over two centuries of sidearms issued, few of them became real reference points, designs that made the institution reconsider the capacity, ergonomics, ammunition commonality, or even the manner in which a pistol dismantled on the bench of an armorer. These five that followed earned reputations by making the definition of the term standard issue different during their time.

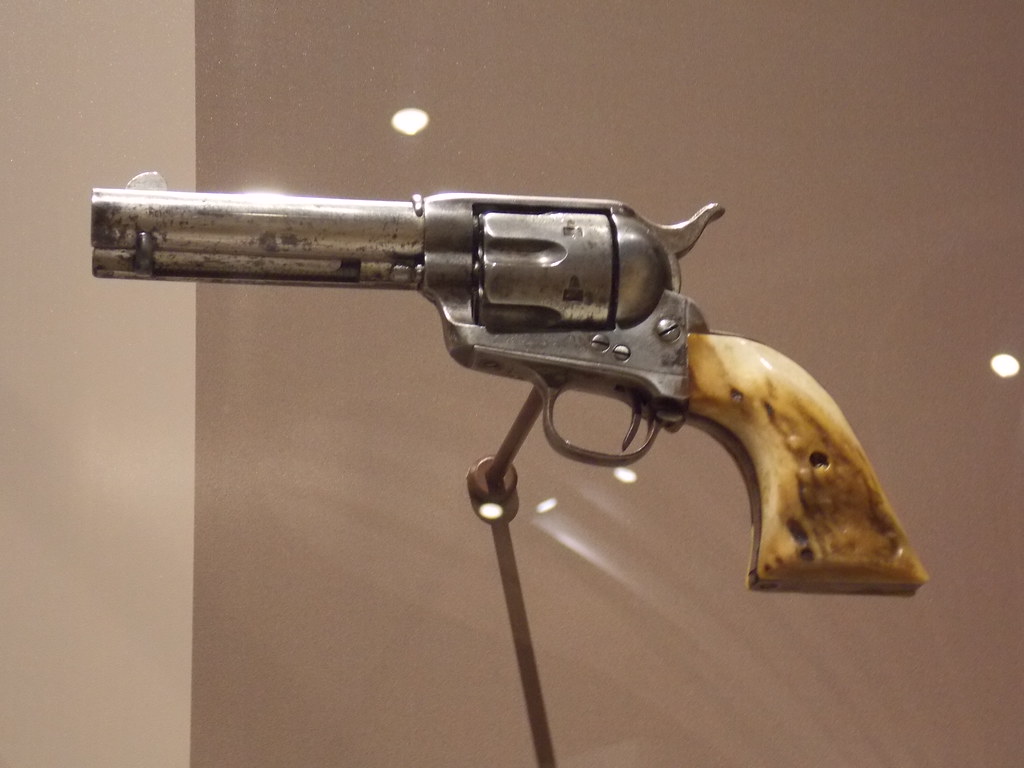

1. Colt Single Action Army (Model 1873)

The Model 1873 “Peacemaker “came at a time as the Army was decisively in the metallic-cartridge era, when it was no longer whether a sidearm could fire reliably but whether it could stand abusive service with uneven service. Its one-action mechanism was still mechanically simple, and that simplicity was important in an Army still constructing that support culture the maintenance of spares, inspection, uniform ammunition, which makes a service weapon last.

Its greater institutional influence was that it established expectations regarding a mighty.45-class sidearm cartridge well ahead of the semi-automatic time. As subsequently available handguns offered quicker reloading times and higher firing rates, the history of the Peacemaker continued to remind that one of the procurement imperatives: when training pipelines and field maintenance are at a disadvantage on the technology curve, rugged design usually continues.

2. Colt M1911 / M1911A1 (.45 ACP)

The M1911 was not just a replacement of the revolver but it assisted in professionalizing the Army-semi-automatic relationship with the pistol. Adopted in 1911, it was the result of a lengthy hunt to find a dependable self-loading design, and a trial culture of the era that valued longevity shooting and repeatability of operation more than novelty. A punishing test which has been quoted as one of the standards prevailing at that time was one in which 6,000 rounds were fired in one and a half days with one pistol, a stress pattern that indicated the extent to which the Army was no longer taking mechanical reliability lightly.

The package provided engineering influence: it was an locked-breech, recoil-operated system that was scaleable and easy to service. The subsequent M1911A1 revisions (codified in 1926) showed a different type of influence, and how a platform might be ergonomically tuned without being unusable in other parts interchangeability, or depot repairability. The 1911 pattern was still a measuring stick within training and requirements writing, even after replacement, institutional inertia at its most permanent.

3. Colt & Smith and Wesson M1917 Revolvers (.45 ACP in half-moon clips)

The M1917 revolvers are the most pragmatic embodiment of the Army: when the production of M1911 could not keep up with the demand, the service converted used large-frame revolvers into type to maintain ammunition compatibility. The big thing was interface engineering. The Army accomplished this with the half-moon clips which ensured a rimless cartridge would act in a revolver cylinder, loading, unloading, and handling it all became acceptable with no modification to the cartridge the supply chain had already committed itself to.

The industrially important stopgap featured a total of 150,000+ (Colt) and 153,000+ (Smith and Wesson) during war times. In addition to the numbers, the idea turned into a blueprint: make logistics lean, innovate faster with hardware, and embrace an alternative operating system in case it makes supply and training predictable in the near term.

4. Beretta 92F/92FS as the M9 (9×19mm)

It begins to sound like systems engineering in the M9 era, when pistol procurement is concerned. The pressure to conform to standardization, ammunition compatibility and the need to have greater capacity drove requirements to the 9x19mm size, the double action/single action running and the magazines that had set a new standard of what normal should have been in a service holster. The 15-round magazine was now a standard that was felted outwards into the qualification standards and the manner in which new shooters were brought into speed.

Equally, the M9 has turned into a piece of lifecycle education. Not only did headline reliability create readiness in long service, but also the discipline of replacing small parts and regular inspection, the fact of an armorer that is not always reflected on the procurement charts. Rails and accessory mounting became a nice-to-have or expected and constant upgrades were a reflection of that change and did not alter the underlying procurement logic that had put the M9 in the field.

5. SIG Sauer M17 / M18 (Modular Handgun System)

M17 and M18 formalized an expectation in the modern era, that a service pistol should be versatile but not too many to maintain. Based on the P320 architecture, the Modular Handgun System used in the Army was based around an already-established design, with modification to match military needs (such as an optics-ready slide cut and internal modification aimed at ensuring small parts remain contained in service) and has been derived. The pistols are 9mm NATO chambered and have a standard 17 round magazine with an optional extended magazine mentioned in program descriptions.

A number of characteristics depict the development of the definition of fieldable by the Army. Steel parts have a corrosion-resistant coating and the design has details that are supposed to minimize the ingression of debris into action. Each pistol is factory tested by a specified quality step; each M17/M18 handgun is test fired, prior to leaving the factory, with 13 rounds. The notion that the accessory ecosystems, such as rails, low-light sights, and compatibility, are now part of pistol procurement and not the handgun as an object, was also solidified through adoption.

The motif that is repeated in these five sidearms is not that of the celebrity or nostalgia. It is the under-glamorous routines of institutional change: How a pistol can be manufactured on mass, kept over decades and woven into the training and logistics without falling down on its own intricacy. Such is the appearance of influence in an Army holster patterns that had been made to work and continued to work whilst the system overall had been learning how to bear them.