Of the 82,774 Winchester Model 1911 SL shotguns that were produced “82,774 left the factory” is no evidence that a design can ship in significant quantities and still be recalled as having influenced its standard user toward unsafe handling.

Notorious guns can hardly malfunction because of a reason. They fail because several minor assumptions coincide: ammunition that is more or less than expected, components that stack compatibility acts against the human tolerance, controls that oppose human reflexes, and a hype cycle that transforms a specialist mechanism into a so-called do-it-all solution.

Next is a walk through repetitive failure modes, mechanical, manufacturing and human-factors, where a brilliant idea could not pass the hands it found itself in.

1. Remington R51

The contemporary re-introduction of Remington 51 attempted to pull the concept of the hesitation-lock to the role of a 9mm concealed-carry firearm. The appeal was justified: low bore axis, a fixed-barrel sensation, and a personality that was not shared with the sea of tilting-barrel striker pistols. The collapse was just as real. Guns of early vintage had earned a reputation of being stop and start and worst of it all is firing out of battery- a safety defect which permanent leaves a stain in a name.

It was not the engineering out-of-execution, but out-of-fit-to-mission argument. A single voice in the industry has openly claimed that Pedersen action could hardly cope with period cartridges, and that the modern 9mm pressure was in the same geometry at its limits, as it was immortalized in the quote, “flawed since the beginning of creation it was designed to serve, this Pedersen action was pushed to its limits, and no further. The quirk of magazine and lockback that the R51 had even after a second generation revision prevented the platform to win back its credibility.

2. Winchester Model 1911 SL

The case study of the 1911 SL is an example of how legal and business restrictions can distort a manual of arms. It was designed to bypass patents of the Browning-era, having no conventional quality charging handle, but being propelled by pulling the barrel backwards to complete the action. That single option formed a handling trap: in a stress situation, the natural movement is an attractive movement to dangerous muzzle position and inappropriate discipline.

The fact that a workaround culture had developed around wearable devices such as buffer rings did not assist in that it introduced another variable of maintenance-related variables into a system that required users to master new motions. The outcome is a design that would not be remembered so much on its mechanics rather on how it was mishandled by normal people in an expected manner.

3. Colt All American 2000

On paper, the All American 2000 by Colt had a viable modern core: a rotating barrel that was supposed to deal with recoil and aid accuracy, and a polymer-frame jump into a market that was turning to capacity-service pistol models. Practically, the production gun was known to have gotten out of control following the concept stage. The trigger weight grew to an area of 12-pound draw making each press a challenge of patience and uniformity.

Production pain is also noted as a community issue that worsened the trigger problem such as out-of-spec barrels in an initial batch and a recall that can later be detected by later-marked frames. The general moral is institutional: later-stage modifications – usually defended on the basis of some sort of liabilities or production choice – can negate the benefits that initially made an architectural design worth constructing in the first place.

4. Glock 44

This was a matter of assignment rather than an ambition by the Glock 44. A rimfire instructor in a brand name aimed at reliability is compared to expectations of centerfire, although .22 LR is variable in nature. Early termination narratives crashed, however, a more refined fact is longer-round-count usage where there have been documented runs of about 5,000 rounds with a small number of failures that were traced back to ammunition bulk discrepancy.

The engineering lesson is one of tolerance: rimfire timing tolerance is smaller, ignition of less reliable, and the platform is held responsible as the ammunition behaves in ways intolerable to other .22s.

5. Smith & Wesson Sigma Series

The heritage of the Sigma is a lesson that reliability is not a panacea to save even a pistol when it comes to bad decisions in the user interface. A dense, unspecified trigger made all comparisons a loss, particularly with striker-fired buyers starting to use the trigger as the main metric of perception of quality.

It also demonstrates how narrative damage may turn into the magnifier of a technical issue. When a gun has been long branded, as the one with the bad trigger, all other vices are the less labored to overlook–and the less excused.

6. Armatix iP1

The iP1 tried to include the access control by mandating a paired watch close to firing. That implied that radios, authentication, lockwork, and behavior that depends on the battery would all have to work perfectly in actual practice. The outcome was a unique firearm that was evaluated at the same time as a mechanical mechanism and an embedded system.

When the problem of trust was demonstrated by passing through the locking system using magnets with a price of 15 dollars, it grew bigger. The point of the product is destroyed when the so-called safety aspect turns to be its most infamous drawback.

7. Mossberg MC1sc

The MC1sc demonstrates that the tolerance cliff of a feature designed to minimize risk may create its own tolerance cliff. In a move that added to ergonomics Mossberg offered their Safe Takedown System with no trigger disassembly required – an ergonomic victory that was responding to an actual, repeated handling error in the industry.

But a narrow combination was reported in the case of extreme testing which showed that a certain hot load was a factor that caused the pistol to come apart, and the fix was apparently a slight change in tolerance of the striker/backplate-associated components after considerable validation. The algorithm worked until it encountered an edge case that a real world design would not make.

8. Kimber Solo Carry

Ultra-compact pistols that are 9mm thrive and die on operating envelope. The Solo Carry was a warning lesson since its reliability margin was perceived to be too tight to accommodate common human factors: mixed train ammunition, different profiles of bullets and imperfect maintenance intervals.

The recurrently popular demand of 124-grain or heavier premium ammunition was more than a footnote; it redefined the pistol as a carry-anywhere implement, and this is an approximation in a category that is constructed of pardoning use.

9. Desert Eagle .50 AE

The Desert Eagle is not a technical failure so much as a mismatch between myth and mission. Its gas operation and load preferences are part of the deal, as is its size and mass. It delivers a dramatic shooting experience and an unmistakable silhouette, but it gets graded often unfairly against the silent expectations applied to everyday handguns. It is a prime example of a platform that can succeed culturally while still failing the “general-purpose” test users subconsciously apply.

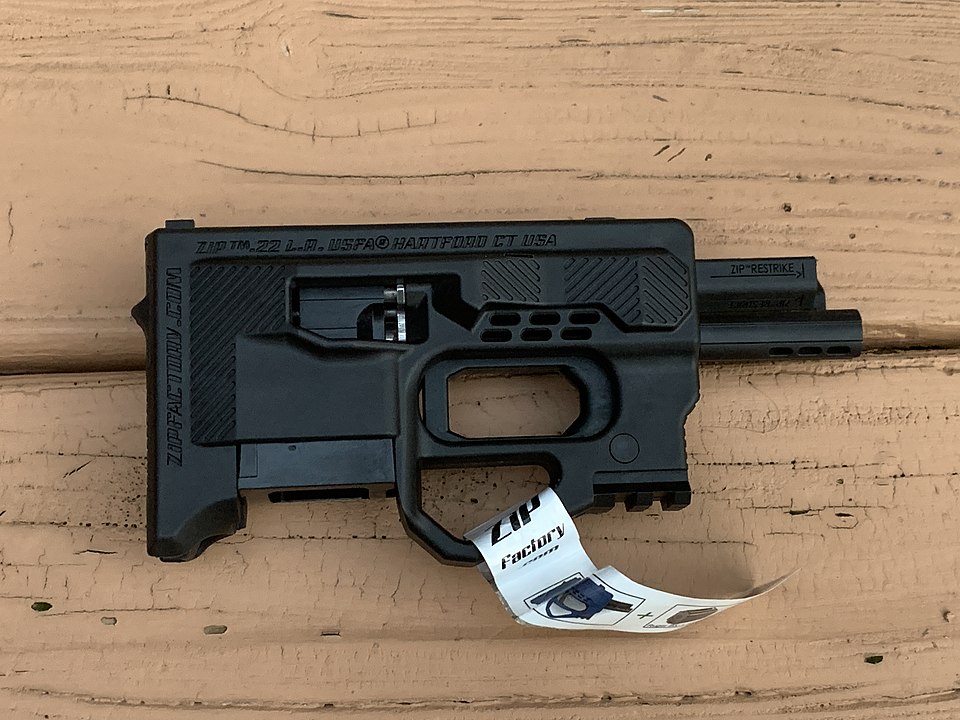

10. USFA ZIP .22 LR

The ZIP .22 is what happens when novelty, cost targets, and incomplete extraction/ejection engineering collide. In order to simplify manufacturing, the design famously eschewed the use of either an extractor or ejector, leaving function dependent on a narrow balance of bolt travel, mass, and ammunition behavior. That is a brutal bet in rimfire.

Accounts of persistent malfunctions failures to extract, double-feeds, and short “runs” before stoppages turned the ZIP into a cautionary object lesson. Worse, the project’s financial gravity reportedly helped sink the company that once had a strong reputation for traditional revolver work.

Across these designs, the repeating pattern is systems behavior: narrow tolerance windows, ammo sensitivity, and user interfaces that punish normal human inputs.

Reputations do not usually break on one dramatic flaw. They break when small, predictable stresses arrive all at once and the mechanism, the manufacturing plan, and the marketing story cannot absorb them together.”