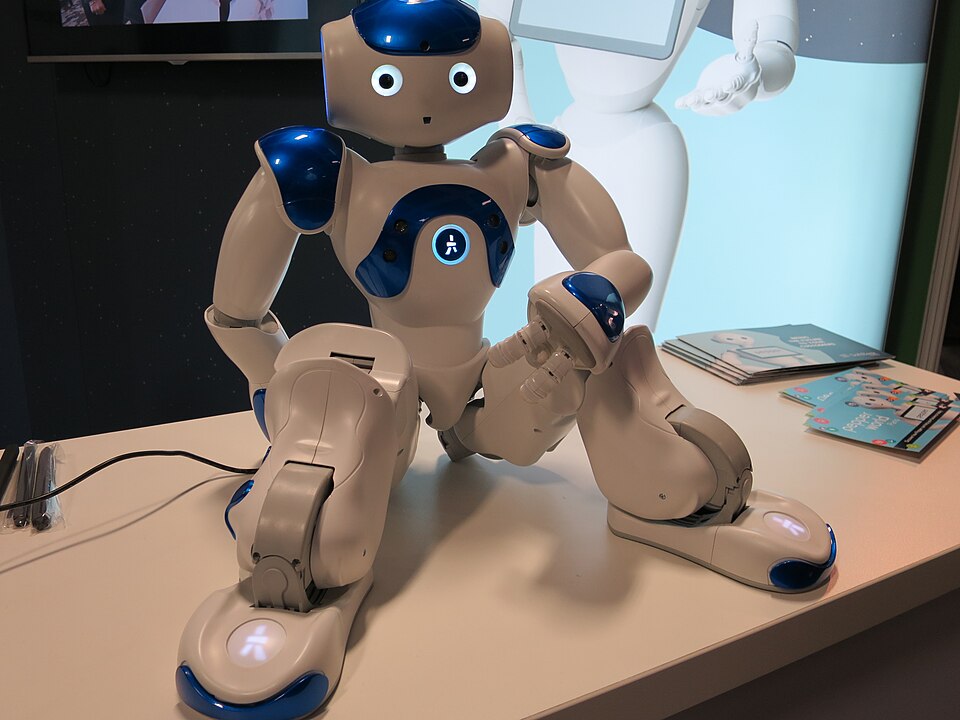

In such a packed auditorium at the Computer History Museum, the hopes and fears added a reality to the event that was quite palpable. Before such a crowd of more than 2,000, with the Humanoids Summit being attended, talk show participant and venture capitalist Modar Alaoui, who once said “robotics is boring, honestly” at a previous talk, added, “Humanoid robots or a different kind of physical embodiment for AI are going to be the norm.” However, with a demo show that displayed the animated Disney Olaf and a Chinese-built Unitree, a realistic outlook by skilled engineers indicated a tough road to undertake for general-purpose robots.

1. Generative AI and Visual Language Models as Catalyst

“The paradigm shift caused by generative AI has made it possible to move robots from being specialized production equipment towards a possible general assistant.” “Current vision-language-action computers enable robots to interpret visual inputs, follow oral commands given in words, and perform complex actions.” “With the integrated multi-modal sensors that include sight, sound, and touch, it is possible that these robots can ‘learn from demonstration without programming.’ Just like how the development of self-driving cars created an enormous amount of information that they could use to improve their ability to drive in various environments, there is ‘much more diverse environments than roads and traffic.”

2. The Dexterity Gap

Even though compliant actuators and touch sensors have been developed, dexterous robotic hands have never been as dexterous as a human hand. This is due to the fact that a human hand has a total of 27 degrees of freedom, while a humanoid robotic hand has only 21; these are provided by Sanctuary AI. Unfolding clothes and peeling fruits and veggies can be a mission to these robotic engineers. They are doing their level best to incorporate a suction cup gripper or a three-fingered robotic hand as per their requirements in the industry; however, the issue of accuracy restricts them.

3. Limitations Imposed By Mobility

The humanoids can move upwards and downstairs and through narrow corridors and working spaces where human activity is centered but the technology used in the batteries of the humanoids is currently hindering the life span of the operation. The life span of the operation is still between two and four hours and is certainly not within the operational hours of the working cycle of a day. The operation involving heavy lifting and involving torqued functions reduces the life span of the operation; furthermore, the supporting infrastructure is very basic for that matter. The UBTech Walker S2 from China has self-changing battery technology that can make it operate for 24 hours and will surely make the tone if the current cost is halved.

4. China’s Strategic Play and Ecosystem Advantage

Today, the point is that it was not a random process that has resulted in the development of China’s humanoid robots. Everything has been possible because of incentives like the creation of a humanoid ecosystem by the year 2025 to make companies like Unitree and UBTech market leaders. The humanoid robots have been able to perform various tasks at Zeekr’s EV factory without resting even for a single day as a human being. Billions of investment dollars were being poured into various sectors like either the AI chip or the sensor technology fields within the Shanghai province.

5. Use Cases in Industry and Market Maturity

The applications of the shortest-term solutions will be in controlled environments like warehousing, manufacturing, and logistics. The Agility Robotics Digit with reversed and bird-like limbs has already started the movement of totes in a distribution center in Texas. In the Chinese market, the application of Autonomous Mobile Robots will address the weakness of Automated Guided Vehicles in being able to adjust to the dynamic e-commerce environment that is emerging now and will continue to emerge in the future years to come. The market of the warehousing automation industry will reach a total of $112 billion in 2029 as projected in a McKinsey report.

6. Challenges of Supply Chain and Standardization

Precision actuators, torque sensors, and planetary roller screws constitute an ongoing supply chain problem for which components come from very few sources. Lack of standardization in this sector prevents scalable growth, while additional costs of tailored combinations of hardware or software represent an issue. Lack of standardization in customized structure of robots heightens the level of complexity, while non-interchangeable parts comprise the standard practice for most types of robots in this industrial sector. Lack of standardization has presented itself in an initial division of electric automobiles, ultimately combined by decreased costs.

7. Hardware Innovation Bottlenecks

The computation required for physical AI work requires a heterogeneous architecture with CPUs, GPUs, perception processors, reasoning processors, and other specialized processors. However, the inefficiency of the computation methods’ “one chip fits all approach to computing and memory technology and memory hierarchy technology is already comparable to the needs of a nation’s energy needs.” Scientists have projected the possibility of a super computational supercell computing chip with memory and logic integrated in three dimensions with the possible potential of up to 80% reduction in power usage by shortening the memory distance to nanometers.

8. Economics & ROI Pressures

The humanoid robot produces by taking $30,000 to $150,000 for a unit while requiring a total deployment cost of $250,000 at max. The return on investment may take over two years while considering the down time for maintenance and the additional cost to make it more deteriorating. In meeting its acceptance on a vast scale, there will be a need to decrease the amount and further lower the return time in non-margin businesses.

9. Organizational Readiness and Workforce Integration

Apart from the field of engineering, there will be a need to develop ‘adaptations in the workforce.’ “More attention will have to be paid to areas such as operator safety and training; obviously negligence will not work here.” However, these will ‘likely weigh less than their current models and will still be dangerous if they fall apart.’ There will also become a necessity to learn ‘how to maintain, program, and simulate the robot functions and processes.’ The robotics industry is facing a critical juncture.

It came out due to ‘very successful merging of generative AI research and sensors and policy research and policy.’ However, ‘robustness and power and cost problems make it very hard to accomplish and very challenging! It’s a tough call even for technocrats and investors and politicians to achieve; to somehow combine the best elements of both hardware technology development and AI research and develop with the best elements of mass production; may possibly overreach reality even though it possesses great potential and prospects.’