The idea of harnessing a non-trivial amount from the Sun in orbit is not some sci‑fi concept that will stay in Musk’s head but rather is a near‑term engineering target. In his most recent comments, Musk set out a sweeping convergence of Tesla, SpaceX, and xAI capabilities anchored by solar‑powered AI datacentre satellites, regulatory pushes for Full Self‑Driving in Europe, and the industrial ramp of Tesla’s Optimus humanoid robot. To investors and technologists, the through‑line is clear vertically integrated AI systems from orbit to factory floor, meant to work at planetary scale.

1. Solar-Powered AI Datacenter Satellites

Underpinning Musk’s orbital AI vision is the physics of space-based solar power: in orbit, photovoltaic arrays can collect as much as 40% more energy than their ground installations, because there is no atmospheric scattering and no weather losses. These satellites would be home to radiation-hardened AI supercomputers designed to cope with deep-space thermal swings-from +120°C in sunlight to -100°C in shadow-requiring multi-layer insulation, heat-pipe radiators, and phase-change materials. Energy could be transmitted to Earth via high-frequency microwave or laser beams, a technology already demonstrated in small-scale terrestrial tests. The data centers themselves would be built using fault-tolerant, AI-optimized processors leveraging xAI’s large-scale models for autonomous operations in both orbital data processing and Earth-side applications.

2. Convergence of SpaceX, Tesla, xAI

SpaceX brings launch cadence and satellite bus engineering, Tesla brings energy storage and thermal management expertise, while xAI brings the AI stack. Musk framed this as a “confluence” of competencies-where battery chemistries proven in Tesla vehicles could be adapted for orbital use, and AI training pipelines could run in space to reduce Earth‑based compute bottlenecks. This is an integration not unlike what Starlink does, but with far higher on-board processing power aimed at AI inference and model deployment.

3. Starlink’s Direct-to-Cell as a Precursor

Recent direct‑to‑cell rollout in Ukraine gave a glimpse of how orbital infrastructure can harden terrestrial networks. The adoption of Starlink’s LEO‑based SMS service-soon to expand to voice and data‑by Kyivstar proved that standard 4G smartphones could link directly to satellites sans extra hardware. In wartime conditions-blackouts lasting up to 12 hours and destruction of as much as 70% of generation capacity-such redundancy is not a matter of convenience but a question of survival. The same kind of resilient link architecture may underpin global AI-satellite connectivity, enabling seamless data exchange deep in disaster zones.

4. Full Self‑Driving’s European Push

Tesla FSD-supervised-is aiming for a February 2026 demo for Dutch regulator RDW, the key to possible EU-wide approval under Regulation 2018/858. There are several steps in this process: national type-approval, controlled on-road testing, and an exemption vote at the European Commission. To establish safety, Tesla’s internal testing has surpassed 1 million km across 17 countries, but RDW underlined that “whether this timeline will be met is yet to be determined” and that road safety is the top priority. For investors, the regulator’s green light can unlock a high-margin software revenue stream across the continent, but timeline risk is material.

5. Neural Networks Across Domains

The same vision‑based neural networks powering FSD are being adapted for Optimus. Whether steering a car through an unprotected left turn or guiding a bipedal robot’s gait over uneven terrain, Tesla’s AI stack processes raw photon streams into control actions. First‑person human demonstrations and third‑person generalization are part of the training loops where simulation‑to‑real transfers mean cars and robots alike constantly improve from the data of the fleet.

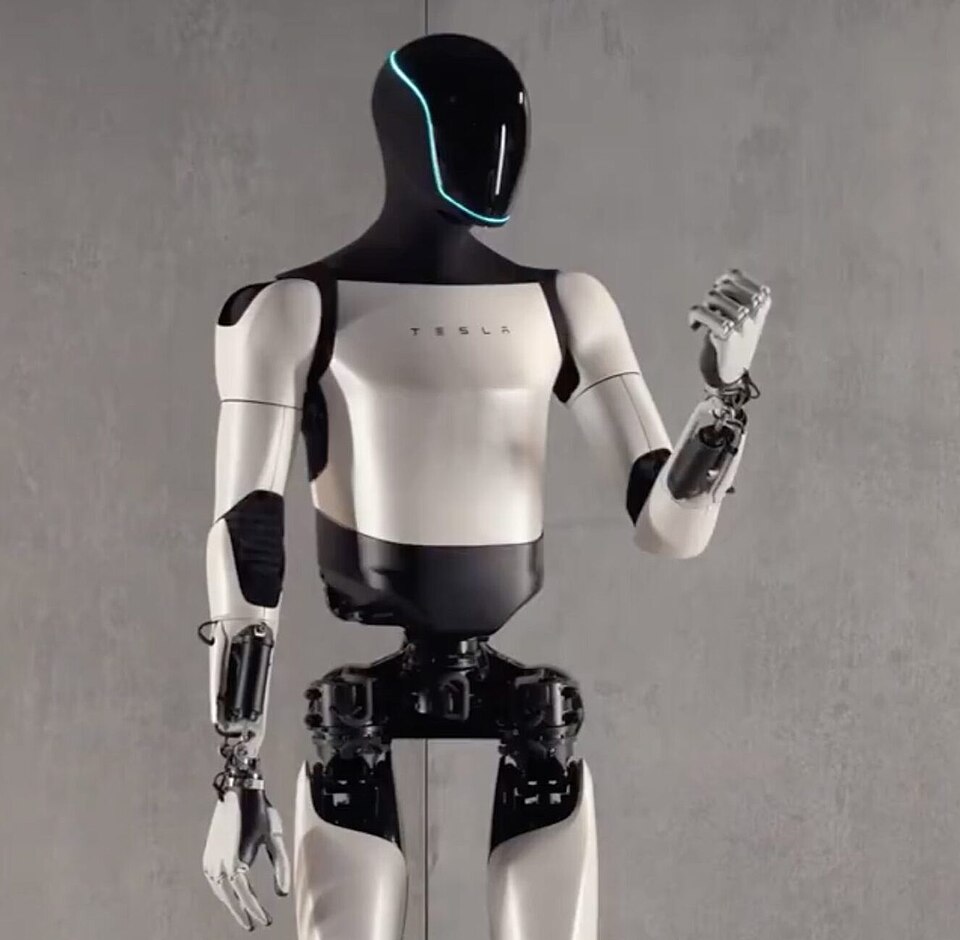

6. Optimus: From Prototype to Million‑Unit Scale

Tesla’s Optimus Gen 3, set to be revealed in Q1 2026, features hands with 22 degrees of freedom, a 45‑lb carry capacity, and increased balance for dynamic environments. Vertical integration includes custom actuators and joints-manufacturing all in house. The production roadmap contemplates low‑volume internal deployment in mid‑2026, scaling to million‑unit annual production on high‑volume lines by the end of 2026. One early use case is to take on tasks in Tesla factories, where one Optimus could perform like five human workers, 24/7 when tethered.

7. AI-Enhanced Dexterity and Interaction

Optimus’ control system includes xAI’s Grok LLM for decision-making and natural language interaction, which lets it understand ambiguous human commands. Tactile sensors in its hands provide feedback for delicate tasks such as handling an egg, folding laundry, or manipulating industrial parts. Capable of all that, plus 5-mph mobility and the capacity to deadlift 150 lbs, Optimus is both industrial and a domestic replacement for labor.

8. Market and Supply Chain Implications

Beyond engineering, there are other implications of the convergence of those technologies. Rare‑earth export restrictions from China might affect Optimus’ actuator magnets orbital AI datacenters would need secure, high‑throughput downlinks and international spectrum coordination. If FSD wins EU approval, software margins could help make up for hardware price pressures brought on by declining EV sales in Europe, where Tesla’s registrations fell 48.5% year‑over‑year in October.

For space‑based AI, early deployments could serve the markets for defense, telecom and disaster response before scaling to consumer services. Musk’s roadmap for 2026 isn’t a portfolio of disparate bets-it’s a vertically integrated stack in AI, energy, robotics, and space. Whether it is satellites gathering solar energy or humanoid robots stitching together EVs, the common denominator is autonomy at scale, constructed on shared AI infrastructure and manufacturing discipline.