Was it really possible for one mislabeled wire to take down a major bridge in the United States? The National Transportation Safety Board investigation into the Francis Scott Key Bridge disaster has unraveled a chain of preventable engineering and operational failures across shipboard electrical systems, maritime safety protocols, and structural vulnerability to result in one of the most catastrophic infrastructure losses in recent memory.

1. The Fault Hidden in Miles of Wiring

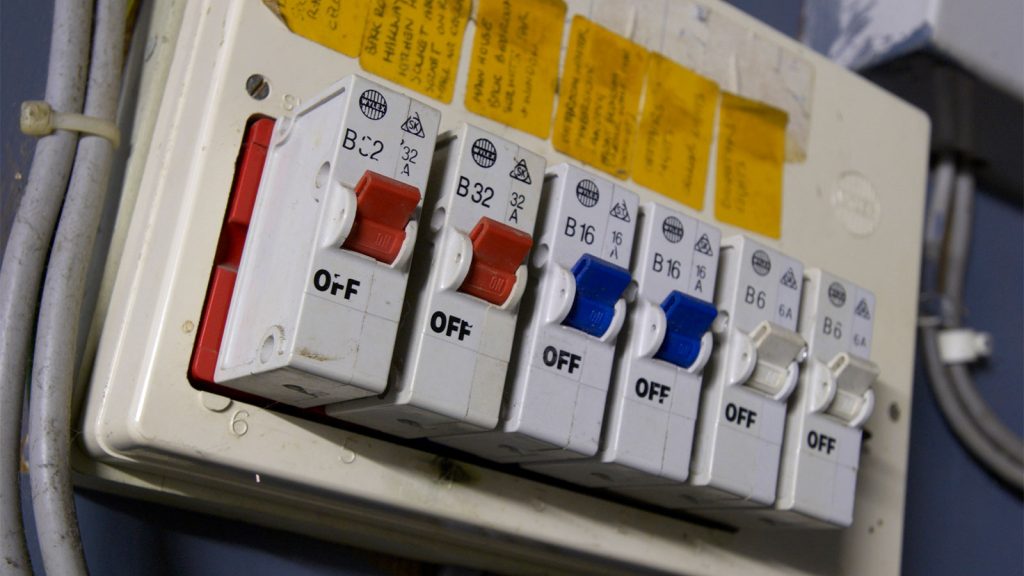

The 984‑foot, 100,000‑ton MV Dali was as long as the Eiffel Tower is tall, with miles of wiring and thousands of electrical connections. Among them was a single signal wire, mislabeled during construction nearly a decade earlier. That incorrect label prevented a secure connection in a circuit breaker. Over years of vibration and shipboard movement, the wire loosened. As NTSB senior marine engineer Barton Barnum explained, “This was an intermittent electrical issue failure, meaning it didn’t fail all the time.” But on March 26, 2024, it failed at the worst possible moment.

2. Dual Blackouts and Loss of Control

The first blackout lasted 58 seconds, disabling steering, the bow thruster, water pumps, and most operational lighting. Crew quickly reset the breaker, but a critical fuel supply pump designed only for flushing lines during maintenance had to be restarted manually two decks below in near-total darkness. NTSB Chair Jennifer Homendy explained, “To restart it, you would have to go two levels down in near total darkness with a flashlight from the engine control deck to the purifier room on the fourth deck.” That restart never happened in time. The generators ran dry, triggering a second blackout just three ship lengths from the bridge.

3. Lack of Redundancy in Critical Systems

Large cargo ships usually have several layers of redundancy for propulsion and power, which includes backup fuel pumps and segregated electrical buses. In this instance, the flushing pump had no backup and had been running continuously for at least seven months-well outside its intended use. That left the Dali without a fail-safe when the primary fuel feed was interrupted-a violation of best practices in maritime engineering, where critical systems are to have redundant, independent backups.

4. The Missed Minute and Twenty-Nine Seconds

As the helpless Dali floated toward Pier 17, Maryland Transportation Authority police were notified and halted vehicle traffic 48 seconds before impact. But they did not contact the construction inspector supervising a crew of seven road workers. “Had the highway workers been notified of the Dali’s emergency at the same time as the MDTA police officers, there would have been about 1 minute and 29 seconds to evacuate before pier 17 collapsed,” said NTSB highway factors engineer Scott Parent. The bridge gave way beneath six of the workers, killing them.

5. Structural Vulnerability Far Above Acceptable Risk

Investigators calculated that the Key Bridge had nearly 30 times the acceptable collapse risk for a critical bridge if struck, based on American Association of State Highway and Transportation Officials (AASHTO) guidance. Built before 1991, it had never undergone a modern vulnerability assessment. The Maryland Transportation Authority had not assessed its vulnerability to ship impact, despite its location over a major shipping channel.

6. No Impact Protection Systems

Since the 1980 Sunshine Skyway Bridge disaster, AASHTO specifications have required either designing piers to withstand calculated ship impact forces or installing protective barriers such as rock islands, dolphins, or energy-absorbing fenders. Civil engineer Sherif El‑Tawil estimated the Dali’s impact force at 30 million pounds, nearly five times the pier’s capacity. No protective system visible or otherwise was present at Pier 17. Modern designs for bridges in high‑traffic waterways often feature massive pier collars or standalone deflection structures that are designed to dissipate such forces before they reach the main supports.

7. Greater Dangers with Bigger Cargo Ships

The Dali’s size reflects a global trend toward ever-larger container vessels for economies of scale. These ships carry greater kinetic energy at any given speed, raising the engineering challenge for bridge designers. A bridge designed for the vessel dimensions of the 1970s or 1980s may be critically under‑protected against today’s behemoths. The NTSB noted that “increasingly larger cargo vessels pose increased risks and challenges to maritime safety,” and urged updates to both shipboard redundancy standards and bridge protection guidelines.

8. Wider National Implications

Since the collapse, the NTSB has found 68 other U.S. bridges that span navigable waterways-many iconic-that were built prior to 1991 and do not have updated vulnerability assessments. Thirteen so far have been assessed to surpass acceptable risk thresholds. The structures include such spans as Pennsylvania’s Betsy Ross Bridge, Louisiana’s Huey P. Long Bridge, and both spans of the Chesapeake Bay Bridge. Overall, the agency has called for 17 safety recommendations to ship owners, bridge authorities, and regulatory bodies, but compliance is voluntary.

The Francis Scott Key Bridge collapse was the result not of a single failure, but of several preventable breakdowns electrical, mechanical, procedural and structural interacting in rapid succession. From a mislabeled wire deep inside a ship’s breaker panel to the absence of a concrete or steel barrier in the river, each gap in engineering safeguards magnified the consequences of the others.