By 1945, American factories had attained a wartime production so enormous that General Motors’ former president turned military production chief, William S. Knudsen, was able to say that the enemy had been “smother… in an avalanche of production.” Behind that avalanche, however, was a tapestry of companies whose genesis ran from the dusty streets of the Old West to the hangars of pioneering aviation. Some had made revolvers for frontier sheriffs, some had made luxury cars, but all were pulled into the World War II crucible.

This was not just a tale of machinery it was an industrial, identity, and engineering makeover. Government orders, “cost-plus” contracts, and the pressures of international war forced companies to remake themselves in a single night. Doing so, they created weapons that became symbols of the war and had an impact both on the battlefield and on the legacy of American industry. These are nine of the most fascinating examples of that makeover.

1. Winchester’s Shift from Lever-Action to M1 Carbine

Famous in the late 19th century for its lever-action rifles, Winchester Repeating Arms fell into financial ruin following World War I. Under Olin Industries’ umbrella, the firm took a conservative 1939 “educational order” for 500 M1 Garand rifles, hesitant to repeat prior debt-fueled expansions. At the end of war, it had made more than half a million Garands.

Winchester’s authentic wartime distinction, though, was the M1 Carbine seven inches shorter and almost five pounds lighter than the Garand. Produced in 1941 under the pressing Ordnance Department needs, the carbine proved invaluable for paratroopers, medics, and rapid-moving infantry. Colonel Martin Reinemann took his through Iwo Jima, and Medal of Honor recipient Audie Murphy used one in his legendary stand against German troops. The portability and rate of fire of the weapon made it popular even among civilians, contrary to the official ban on equipping medical staff.

2. Colt’s .45 M1911A1 A Sidearm with Stopping Power

A product of early 20th-century hardships to replace the inadequate .38 revolver, the Colt .45 Automatic went to war in WWII as the standard-issue U.S. sidearm. Manufacturing was increased beyond Colt to Remington Rand, Ithaca Gun Co., and Union Switch & Signal, producing 1,878,742 pistols in the war.

Its reputation was forged in battle from Guadalcanal, where Master Gunnery Sergeant Sheffield Banta stopped a charging officer brandishing a sword, to Pacific and European theaters where its close-range “stopping power” was valued. Despite efforts by some commanders to displace it with the M1 Carbine, issue actually expanded; by 1945, a Marine division’s authorized pistols had more than doubled from 1942 levels. The M1911A1’s dependability guaranteed its service life far into the 21st century.

3. Boeing’s B-29 Superfortress Engineering at the Edge

The B-29 was the most expensive project of WWII, costing $3 billion $1 billion more than the Manhattan Project. Boeing’s pressurized, radar-equipped “super bomber” could carry 20,000 pounds of bombs over 2,500 miles, but early missions from China faltered under mechanical failures and jet stream winds.

Under General Curtis LeMay, strategy changed to low-level firebombing raids, culminating on March 9–10, 1945, in the Tokyo firebombing that claimed almost 100,000 lives. Altered “Silverplate” B-29s, such as the Enola Gay, dropped atomic bombs on Hiroshima and Nagasaki. The airplanes filled the gap between piston-engine bombers and the nuclear age, postwar serving as America’s main strategic deterrent.

4. North American’s P-51 Mustang From British Request to Escort Legend

Originally constructed for Britain in 1940, the Mustang’s miracle transformation occurred when Rolls-Royce Merlin engines supplanted the initial Allison engines, increasing high-altitude speed by almost 100 mph. Lt. Col. Thomas J. Hitchcock Jr., U.S. Military Air Attaché in London at the time, was an evangelist for the switch, foreseeing it would be “the best fighter of 1943.”

By spring 1944, P-51Bs and later “bubble-top” P-51Ds protected bombers deep within Germany, reducing loss rates and making prolonged daylight raids possible. Through “Big Week” in February 1944, Mustang pilots destroyed 17% of the veteran Luftwaffe fighter force. The aircraft’s range and maneuverability established it a staple from Europe to the Pacific, where Iwo Jima-based Mustangs escorted B-29s over Japan.

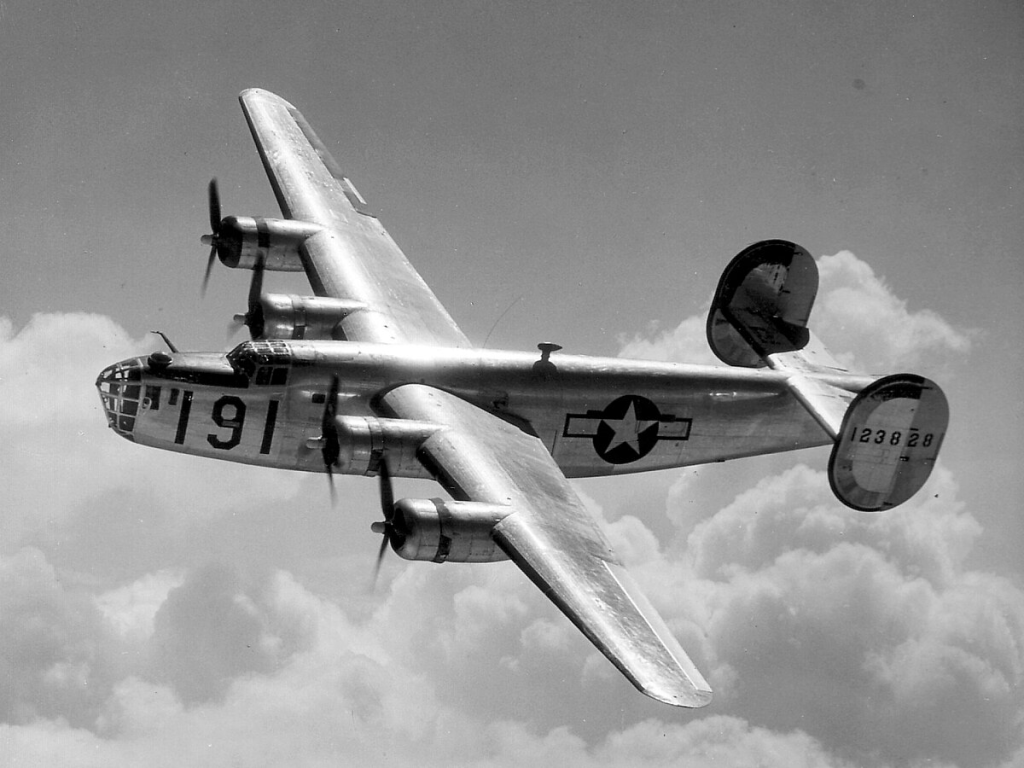

5. Ford’s Willow Run One B-24 Liberator per Hour

By utilizing mass-production techniques in the automotive industry on heavy bombers, Ford’s Willow Run factory was the world’s largest factory under a single roof. Aviation specialists questioned a car manufacturer’s ability to assemble four-engine bombers, but Willow Run was producing a B-24 every 63 minutes by 1945.

The 8,685 Liberators, plus additional kits for almost 1,900 more, produced by the plant made the B-24 the most prolific American military aircraft in history. Ford’s conversion of assembly-line precision to complex aviation production was celebrated by The Washington Post as “the greatest single manufacturing plant the world had ever seen.”

6. Chrysler’s Detroit Arsenal Mass-Producing the M4 Sherman

Asked in 1940 whether Chrysler could manufacture tanks, CEO K.T. Keller confessed to having never laid eyes on one. Within a matter of months, the Detroit Arsenal Tank Plant was rolling out M3s, then M4 Shermans under the power of a welded-together 30-cylinder “Frankenstein” engine generating 425 horsepower.

The 1.25 million square feet of the plant represented the transformation from car production as a luxury item to armored warfare, providing thousands of tanks that led Allied pushes in Europe. Chrysler work exemplified how civilian engineering talent could be quickly adapted to accommodate military requirements.

7. General Motors The Biggest WWII Military Contractor

GM’s war production was phenomenal: 854,000 trucks, 38,000 tank destroyers and tanks, 206,000 plane engines, and 1.9 million machine guns. Divisions such as Buick and Cadillac manufactured aircraft engines, and Oldsmobile made artillery parts.

GM also produced TBM Avenger torpedo bombers under license from Grumman, and its production of artillery shells exceeded 119 million rounds. GM’s size and variety of production, with $12 billion in contracts, made it a vital part of the Allied war effort.

8. Sikorsky’s R-4 The First Combat Rescue Helicopter

Igor Sikorsky’s R-4 was the world’s first mass-produced practical helicopter, entering service in 1943. Initially intended for training, it proved invaluable in rescue missions over difficult terrain.

In April 1944, 2nd Lt. Carter Harman piloted a YR-4B in the first combat helicopter rescue, extracting downed pilot TSgt. Ed Hladovcak and three wounded British soldiers from a Burmese rice paddy. The mission required multiple trips under threat of Japanese forces, showcasing the helicopter’s unique capability to reach inaccessible locations.

9. Springfield Armory’s M1 Garand “Greatest Battle Implement Ever”

Conceived by John C. Garand and adopted in 1936, the semi-automatic M1 Garand supplanted the bolt-action Springfield M1903. Production during WWII soared, with Springfield Armory and contractors such as Winchester producing millions.

General George S. Patton notoriously referred to it as “the greatest battle implement ever devised.” Its gas system enabled fast, dependable fire, providing U.S. infantry with a critical advantage over Axis troops equipped with slower bolt-action rifles.

These firms, whether products of frontier gunsmithing or city car plants, were pillars of America’s wartime industrial burst. Their products products of necessity, produced on unprecedented scale transformed the battlefield as well as the country’s technological course. By melding Old West traditions with total war requirements, they forged a legacy that still resonates in military history and in the lasting attraction to the machines they created.