The year 2025 was intended to be SpaceX’s proving ground for its Starship. Instead, it has turned into a high-stakes engineering masterclass in troubleshooting, with the two May and June catastrophic failures laying bare weaknesses deep inside the rocket’s systems. Every failure has made engineers grapple with the boundaries of materials, fluid dynamics, and structure design in the biggest-ever launch vehicle.

1. The May 27 Flight 9 Booster Failure

Flight 9 started with a first: the initial reuse of a Super Heavy booster, Booster 14. Following a smooth hot-stage separate from the upper stage, the booster performed a steeper-than-scheduled reentry profile to test aerodynamic boundaries. That experiment came at a high price. Post-flight analysis determined that the higher-than-expected angle of attack put greater-than-predicted structural loads on the interior fuel transfer tube, a vital passage carrying methane from the tank mounted atop the booster to the engines. The tube ruptured, and methane and liquid oxygen intermixed and burned. Telemetry was lost when the booster was approximately one kilometer over the Gulf of Mexico. Future flights will have lower descent angles, although redesigned grid fins from four to three, each 50% larger are intended to eventually restore some maneuverability.

2. Breakdown of Upper Stage Diffuser

Ship 35, the upper stage of Flight 9, initially did well, firing all six Raptor engines. But three minutes into the burn, sensors reported a steady rise of methane in the nosecone. By five minutes, main methane tank pressure plummeted while nosecone pressure went through the roof. The culprit was a malfunctioning main fuel tank pressurization diffuser on the forward dome of the methane tank. NASA’s Marshall Space Flight Center defines a diffuser as an apparatus that keeps high-energy gas from impacting liquid fuel or tank walls directly, reducing heat transfer and decreasing pressurant mass requirements. SpaceX engineers replicated the failure at the company’s McGregor, Texas test facility and re-engineered the component to endure more than ten times the anticipated service life.

3. Methane Pooling and Loss of Attitude Control

Since the diffuser lost pressure, liquid methane accumulated in the forward nosecone section and compromised Ship 35’s attitude control. Reaction control thrusters bridged temporarily, but conditions continued to deteriorate when opposing loads inhibited opening of the payload door to eject eight Starlink simulators. Automated passivation commands blew out all residual propellant, precluding any possibility of in-space engine relighting. The vehicle reentered at an off-nominal attitude and disintegrated over the Indian Ocean 46 minutes into the flight.

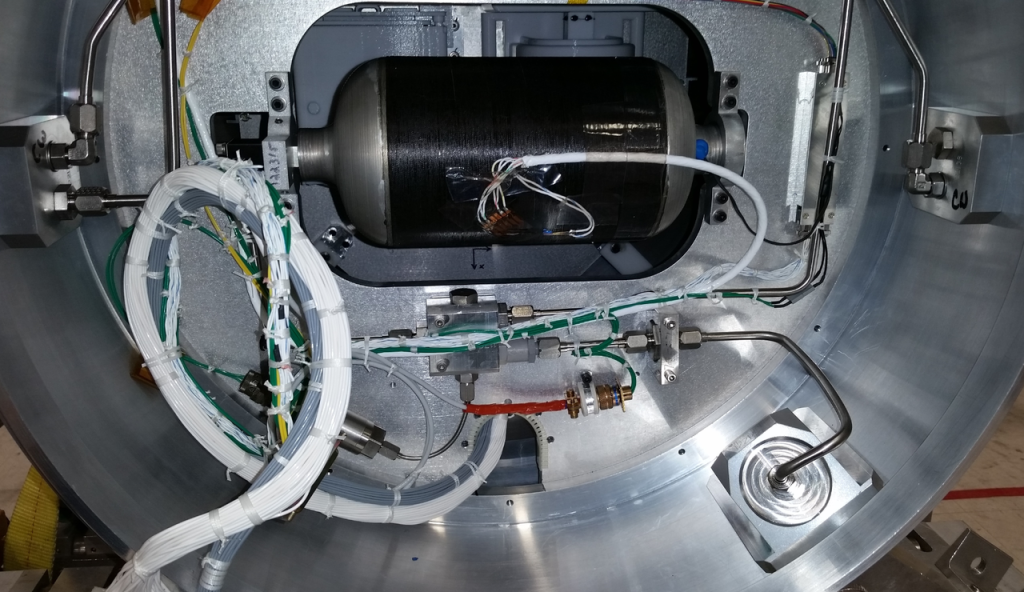

4. The June 18 COPV Explosion

Just a few weeks later, Ship 36 was annihilated in a ground test at Starbase’s Massey facility. The reason: “undetectable or under-screened damage” to a composite overwrapped pressure vessel (COPV) carrying high-pressure gaseous nitrogen in the payload bay. COPVs are thin metallic liner tanks wrapped in carbon fiber composite are ubiquitous in aerospace because of the high strength-to-weight ratio, but susceptible to microcracking, impact damage, and stress rupture. The exploded COPV violently ruptured, initiating propellant mixing and combustion. Fires destroyed adjacent infrastructure.

5. COPV Design and Inspection Reform

In return, SpaceX reduced COPV operating pressures, incorporated protective covers during assembly, and established new proof tests and acceptance criteria. Most significantly, they created a method of non-destructive evaluation to find internal damage, which was an essential step considering COPVs’ history SpaceX lost a Falcon 9 in 2015 because of a COPV-related failure.

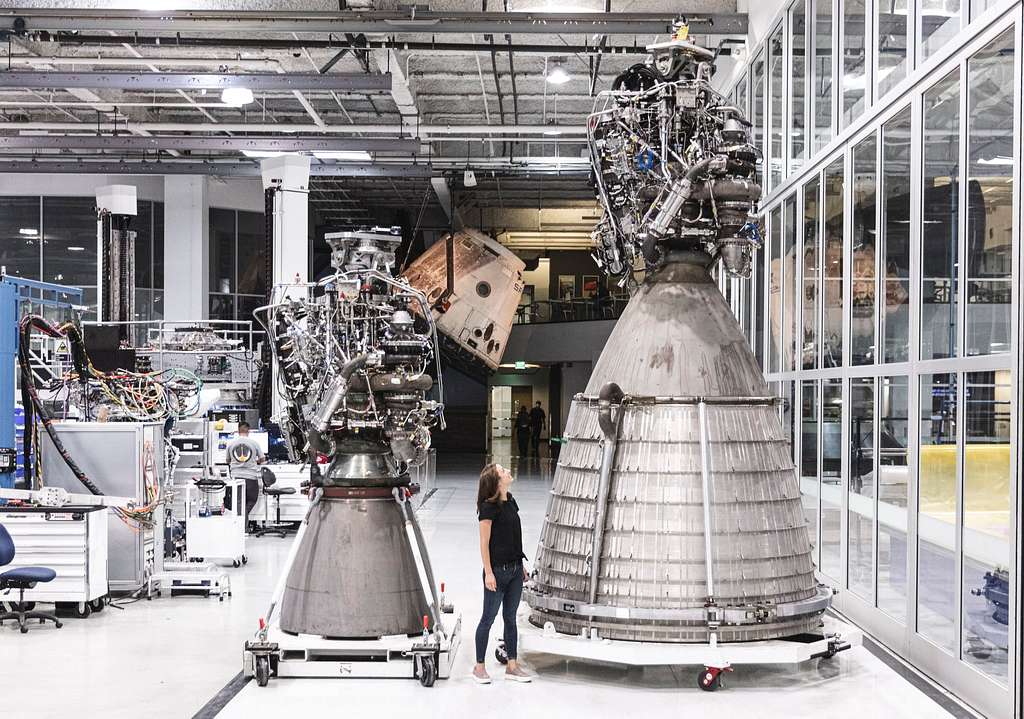

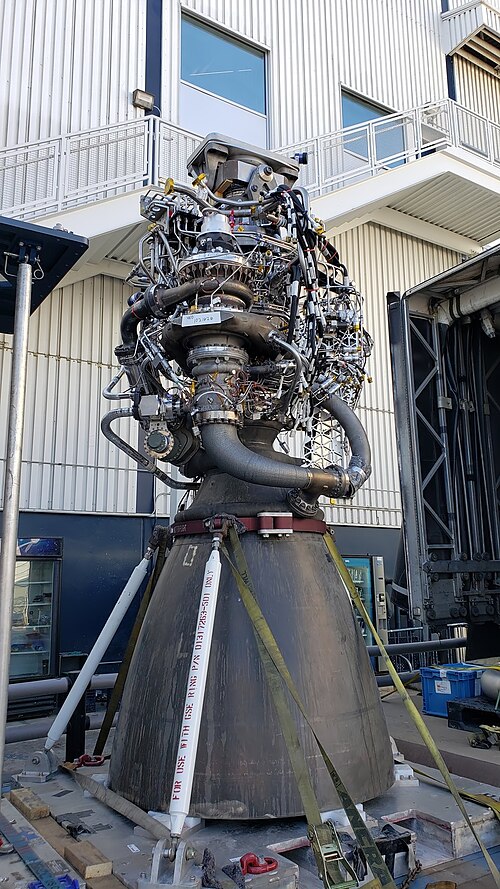

6. Raptor Engine Performance and Reuse

Both failures happened even though overall performance was generally good from the methane-burning Raptor engines. Booster 14 launched with 29 of its 33 engines recycled from an earlier flight, one of which had been flown three times. The high chamber pressures and full-flow staged combustion cycle of the Raptors provide outstanding efficiency, but also require highly accurate propellant management meaning failures in fuel supply hardware such as the transfer tube or diffuser are particularly hazardous.

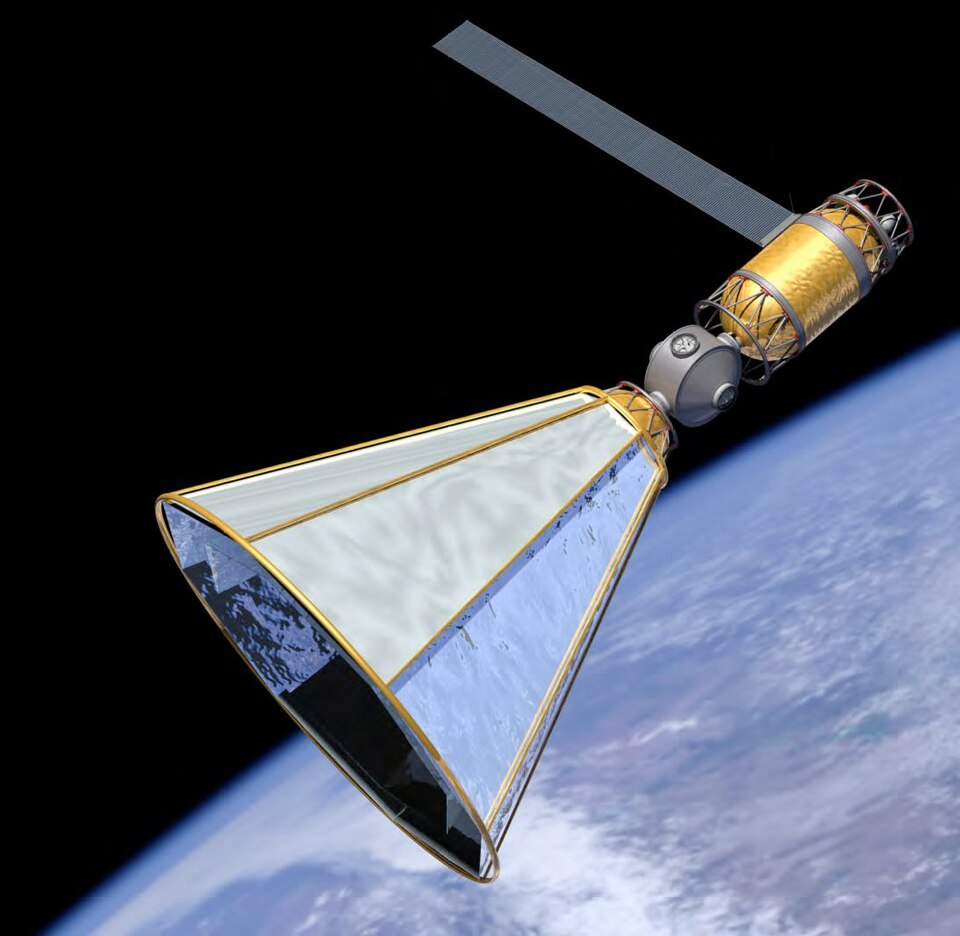

7. Implications for Artemis and Mars

Starship’s troubles ripple far wider than SpaceX. NASA’s 2027 lunar landing target for its Artemis 3 mission rests on a human-certified Starship as its lander. One of the milestone events orbital cryogenic propellant transfer is delayed to fiscal year 2026. Elon Musk has labeled orbital refueling “one of the hardest engineering challenges that exist” and involves getting two Starships to rendezvous in orbit and swap supercooled methane and oxygen without boil-off or slosh-induced instability. Until the reliability of upper stages is enhanced, such demonstrations are beyond reach.

8. The Iterative, Risk-Tolerant Approach

SpaceX justifies its “fly, fail, fix” mantra as being crucial to speed innovation. “All lessons learned, through both flight and ground testing, continue to feed directly into designs for the next generation of Starship and Super Heavy,” the company said. This methodology has provided breakthroughs such as capturing Super Heavy boosters with the “Mechazilla” tower but also comes with high-profile failures that push investor patience and NASA’s trust to the limit.

9. The Path Forward

Two additional Block 2 Starships will launch before the taller Block 3 version arrives later with enhanced Raptors and structural updates. Flight 10, on Aug. 24, will try Starship’s initial payload deployment and several reentry tests, while the booster will check a reserve-engine landing burn sequence prior to splashing down in the Gulf. Success would be the first time a Block 2 Starship makes it through reentry, at last enabling engineers to obtain long-awaited heat shield data pivotal for reuse.

The engineering problems pressurization hardware failure, COPV integrity, aerodynamic load capacity are tractable, but each requires intense redesign, qualification, and testing under flight environments. For SpaceX, the competition is not to Mars or the Moon, but to dominate the physics and materials science that will enable such travel.