The Starship program’s recent string of failures has not been the result of a single weak link, but of a complex interplay of propulsion, structural, and thermal protection challenges. As SpaceX readies Flight 10, engineers are bringing a redesigned methane tank pressurization diffuser, reinforced composite overwrapped pressure vessels, and new heat shield experiments to the pad each a direct response to hard-earned lessons from the past eight months.

1. Methane Tank Diffuser Failure and Redesign

The most recent in-flight loss in May traced back to a faulty main fuel tank pressurization diffuser mounted on the forward dome of Starship’s primary methane tank. Minutes after launch, sensors registered a pressure drop in the main tank and a simultaneous pressure rise in the nose cone, signaling that high-pressure gas was venting into the wrong compartment. The vehicle completed its engine burn, but venting and a worsening leak overwhelmed the attitude control system.

Automatic commands vented all remaining propellant, ending the mission over the Indian Ocean. SpaceX engineers recreated the failure on the ground and redesigned the diffuser to direct pressurized gas more precisely into the tank, a change expected to “substantially decrease” structural strain.

2. COPV Rupture and Pressure Management

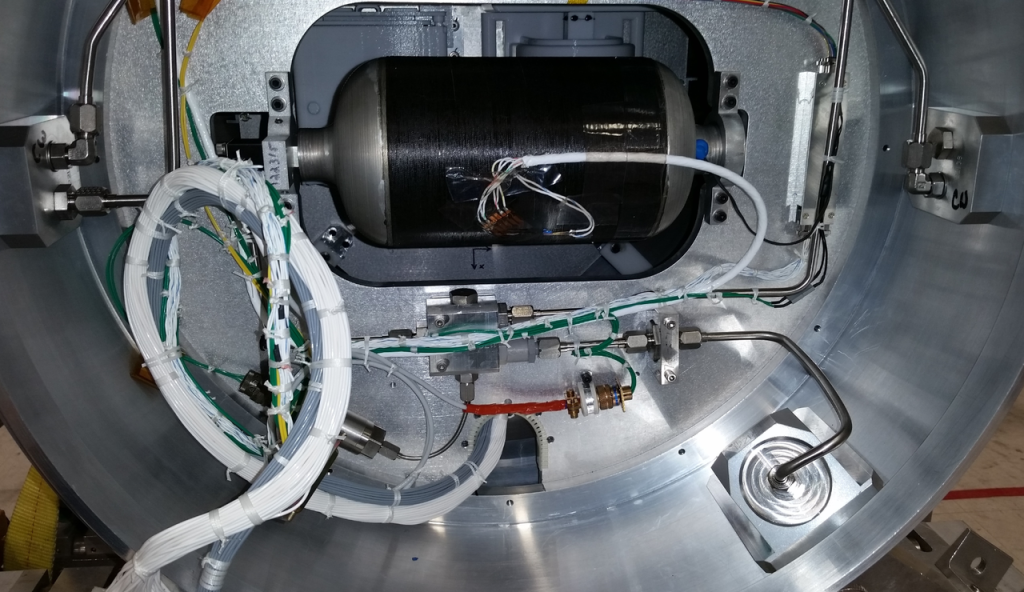

The June 18 ground test accident that destroyed Ship 36 was caused by the violent rupture of a high-pressure nitrogen COPV in the payload bay. COPVs lightweight vessels made of a metallic liner wrapped in carbon fiber composite are critical for storing pressurant gases in cryogenic propulsion systems. SpaceX will now operate COPVs at lower pressures, implement enhanced inspection protocols, require more rigorous proof testing, and introduce hardware modifications to mitigate rupture risk. These measures address a failure mode that can release energy equivalent to small-scale explosives within milliseconds.

3. Raptor Engine Evolution and Reliability Upgrades

The Super Heavy booster’s 33 Raptor engines and Starship’s six upper-stage Raptors remain at the heart of the system’s performance envelope. Failures in earlier flights, including harmonic responses in the vacuum engine feedlines during Flight 7 and a center engine hardware failure in Flight 8, have driven targeted upgrades. These include preload increases on key joints, a nitrogen purge system for the upper stage’s “attic” section, and propellant drain system improvements. Future Raptor 3 engines will reduce leak-prone joints and shrink unpressurized volumes, directly addressing ignition and leak hazards.

4. Heat Shield Material Testing for Reusability

Starship’s stainless steel hull must endure reentry heating far beyond what the Super Heavy booster experiences. Flights this year have tested multiple ceramic and metallic tile designs, including actively cooled variants, to combat tile loss and localized hot spots. Engineers have intentionally removed tiles in certain areas to stress-test vulnerable zones, using embedded sensors to map thermal loads. Data from Flight 10’s reentry will inform Version 3’s thermal protection system, a prerequisite for returning the upper stage to the launch site and for deep-space missions to the Moon and Mars.

5. Booster Landing Envelope Expansion

While SpaceX has already caught a Super Heavy booster with its launch tower arms, Flight 10 will target a controlled splashdown in the Gulf of Mexico to trial new descent profiles. Engineers will test a different mix of landing engines, including completing the burn with only two center Raptors, to validate redundancy strategies. The booster will avoid the high-angle-of-attack descent that contributed to a May structural failure in its methane transfer tube, instead refining aerodynamics for stability and propellant efficiency.

6. Payload Deployment Demonstrations

Flight 10 will carry spacecraft simulators approximating the mass and dimensions of next-generation Starlink satellites. Previous missions failed before reaching this phase, but a successful deployment will validate Starship’s payload bay mechanisms and the “pez dispenser” system designed for rapid satellite release. This capability is central to SpaceX’s plan for high-volume constellation deployment and for future deep-space cargo missions.

7. Preparing for Starship Version 3

Only two Version 2 vehicles remain before the transition to the taller Version 3 configuration. Version 3 will integrate improved Raptors, refined tank geometries, and an evolved heat shield architecture. Every anomaly from diffuser fatigue to COPV rupture feeds directly into these designs. The iterative approach mirrors the development arc of Falcon 9, where successive block upgrades transformed early prototypes into a workhorse launcher.

As the countdown to August 24 approaches, Flight 10 represents more than a return to flight it is a convergence point for propulsion refinements, structural safeguards, and thermal protection breakthroughs. For SpaceX, each test is not just a launch, but a data-rich engineering trial shaping the vehicle intended to carry humans to the Moon, Mars, and beyond.