A nagging question echoes down American launch policy hallways: Will America’s launch complex be able to keep pace with its most advanced rockets and accelerating rate of defense and commercial flights? Recent disclosures by United Launch Alliance (ULA) CEO Tory Bruno offer a glimpse into how one of the sector’s cornerstones is meeting the challenge through a mix of hard-nosed engineering, innovative reusability thinking, and strategically reworking the very launch pads that rockets leave from.

1. Starship Licensing and Range Safety at Kennedy Space Center

Licensing SpaceX’s Starship at Kennedy Space Center (KSC) is going on under unprecedented scrutiny. Tory Bruno called Starship “an interesting vehicle” of “unprecedented size,” and said that its unprecedented rate of launches warrants a strict review by both the U.S. Space Force and the Federal Aviation Administration (FAA). He mentioned a simple operating restriction: “There are certain operations you can’t do on a pad when another vehicle is refueling, due to the ‘energetics involved in that.” It isn’t a matter of scheduling; it’s a simple range safety and risk management problem.

The FAA Starship-Super Heavy Draft Environmental Impact Statement at LC-39A is contemplating up to 44 launches and landings annually, not just looking at environmental impacts, but also cumulative impacts on airspace, infrastructure, and the launch environment as a whole. Bruno’s observation that “the analysis must make sure that the capacity of our nation is larger, not smaller” is a concern shared increasingly by providers: As launch rates increase, so does range coordination, fueling, and emergency response complexity.

2. SMART Reuse: ULA’s Special Path to Engine Reusability

While competitors are offering full booster return, ULA’s SMART Reuse architecture targets the most precious piece of the rocket: the engine module. The SMART component critical design review is complete, Bruno having stated, “By the time that path is done, pretty much the only thing being shed from the booster will be the fuel tanks.” The SMART mission employs a Hypersonic Inflatable Aerodynamic Decelerator (HIAD) for engine section protection on reentry, parachute drop recovery from the sea. This type of design is intended to circumvent mass penalty and in-stage landing complexity. Test flight capability can be brought on as early as 2026, but only in conjunction with customer purchase and subsequent Vulcan performance enhancement. As Bruno clarified, “Recovering the aft of the booster is not the end of the journey for us,” indicating future growth in reusability and greater launch cadence.

3. BE-4 Engine Performance: A Methane-Fueled Leap

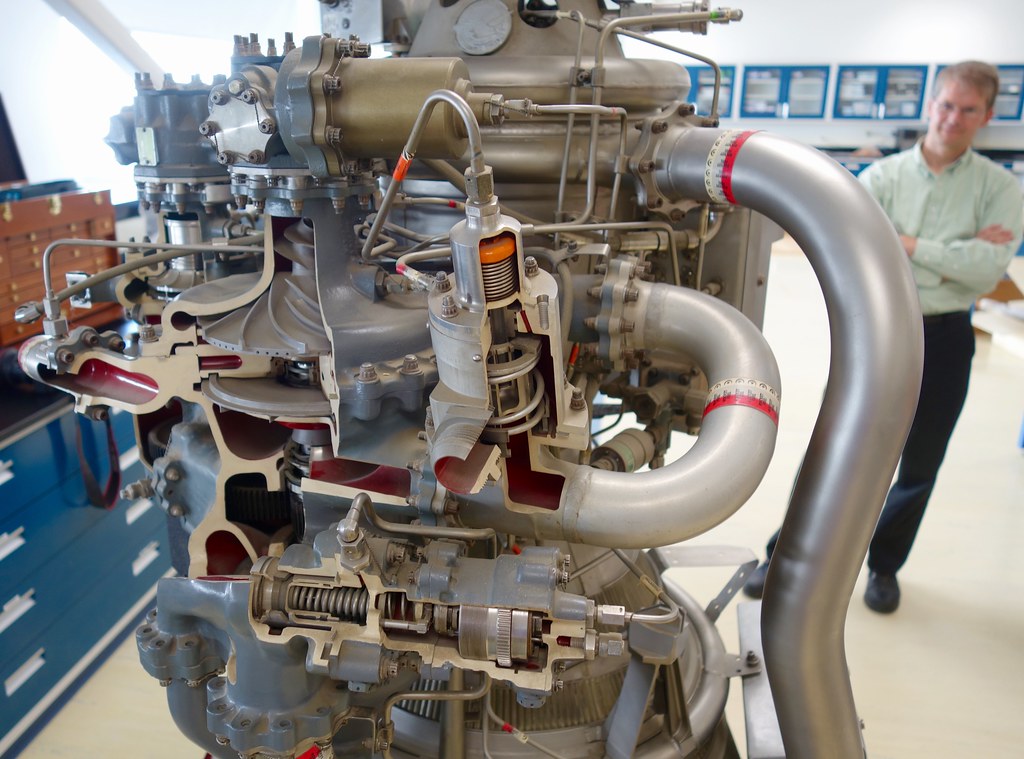

Blue Origin’s BE-4 engine is at the core of Vulcan design. There are two BE-4 engines, each of which has 550,000 pounds of thrust at sea level and is fueled by liquefied natural gas (mainly methane) and liquid oxygen as the propellants. Cleaner combustion of methane over kerosene minimizes carbon deposits, one of the main facilitators of reusability. Bruno praised the engines, calling them “operating beautifully,” and joked, “Don’t tell Dave Limp, but they’re maybe an engine or two ahead.” The BE-4 hydrostatic bearings that reduce wear while optimizing operation life are a specialized reuse design for up to 100 times. Combined with Vulcan’s first-stage modularity, this technological innovation positions ULA to compete not just on reliability but on cost and sustainability too.

4. Infrastructure Growth: The Private Spaceport Equation

ULA’s commitment to Cape Canaveral and Vandenberg is stationary, yet Bruno guaranteed that the company is “examining literally everything” with regard to new launch facilities. Wallops Island stands out as it already boasts infrastructure and good launch slops, already hosting Rocket Lab’s Electron and Neutron and soon the NG/Firefly Eclipse. But Bruno cautioned that a new Vulcan facility will take years to develop, and there is “no immediate push for it.” The actual chokepoint, he claimed, is not steel and concrete, but the capability to bring range requirements together and open launch windows among providers. He urged the government to release more information about range needs so infrastructure can remain ahead of market growth.

5. Environmental and Range Safety Procedures for High-Frequency Launches

The FAA’s environmental assessment process for Starship at KSC is an extension of a broader regulatory focus shift. The Draft EIS addresses not only the short-term environmental impacts of launches noise, air quality, and wildlife disruption but also the systemic impacts of a rate of almost one per week. These practices are now embedded in the philosophy of licenses, and their definition will establish how launch providers plan, price, and invest in new infrastructure. The environmental baseline set by the 2019 analysis is being reviewed with Starship’s evolving operational profile, including higher launches per month and multiple landing pads.

6. Vulcan’s Modularity and Market Strategy

Vulcan’s modularity is a masterclass. The first stage of the rocket, built around the BE-4 engines, can be supplemented with a maximum of six GEM 63XL solid rocket boosters optimized for mission performance. ULA’s Centaur V upper stage, powered by two RL10 engines, provides high-energy precision for direct geosynchronous injection a capability of critical national security value. This flexibility enables ULA to fit a diverse manifest, from Project Kuiper commercial satellites to the most sensitive defense missions. Two payload fairing lengths offer spacious bay space for even the biggest satellites, and multi-manifest hardware allows for rideshare missions for smaller payloads.

7. Launch Cadence, Facility Enhancements, and Workforce Challenges

ULA is moving towards a cadence of about two missions per month on both Vulcan and Atlas fleets in 2025 and 2026, with nine flights scheduled this year. Recent investment in a new Vertical Integration Facility (VIF) and Mobile Launch Platform (MLP) at SLC-41 will enable simultaneous rocket assembly, a major enabler to increased cadence.

West Coast SLC-3 nears certification in the face of across-the-industry skilled trades shortages and supply chain interruption. The payload split will be 40% government and 60% commercial through 2027, reflective of the evolving mix of the launch market. With the Vulcan rocket ready to launch into U.S. Space Force service, the strategy of ULA emerges increasingly clear: balance innovation with operational reliability, develop infrastructure responsibly, and pursue targeted reusability in harmony with economic and technical reality.

As Bruno would put it, “The analysis must verify that our nation’s capability is larger, and not smaller.” The coming years will tell if this plan has the potential to make the vision of a robust, vibrant, and sustainable American launch economy a reality.