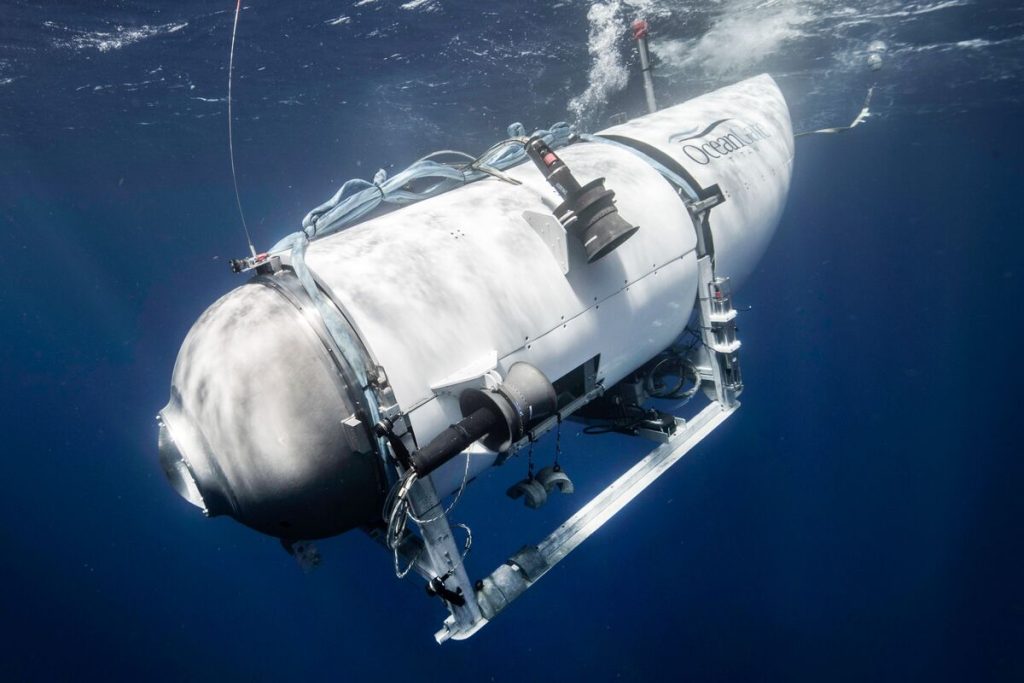

“Carbon fiber is extensively applied to build pressure vessels where the fiber is wrapped around the outside edge of the vessel. This configuration enables such vessels to resist internal high pressure but not necessarily external forces,” said Deborah Chung, professor of mechanical and aerospace engineering at the University at Buffalo. The catastrophic implosion of OceanGate’s Titan submersible in June 2023 has become a case study in the perils of disregarding fundamental engineering principles, regulatory oversight, and the unique demands of deep-sea environments.

1. OceanGate’s Design and Testing Shortcomings

The U.S. Coast Guard’s Marine Board of Investigation delivered a scathing critique of OceanGate’s approach to the Titan’s design, certification, and maintenance. Investigators concluded that OceanGate “failed to follow protocols for safety, testing and maintenance,” and that its chief executive officer, Stockton Rush, “exhibited negligence that contributed to the deaths of four individuals.” The company built with a carbon fiber hull chosen more for its weight-saving and buoyancy benefits than for life-cycle analysis or thorough testing to failure and thus didn’t insist upon all that toughness.

Instead, OceanGate depended on a real-time monitoring system, whose warning thresholds and methodology even employees could not explain. The Coast Guard report emphasized that “no dives were ever aborted due to RTM system warnings,” and three of the eight sensors were “likely inoperable” during critical operations.

2. Technical Anatomy of the Hull Failure

The Titan’s carbon fiber hull, a 22-foot-long pressure vessel, was at the heart of the disaster. Forensic examination uncovered production flaws wrinkles, porosity, voids, and extensive delamination of the carbon fiber layers. National Transportation Safety Board engineer Don Kramer testified that such flaws, with repeated dive cycles, caused step-by-step weakening. The design of the hull did not provide for “expected cycle-life,” and OceanGate continued to use the vessel following accidents, such as a loud acoustic event in 2022, without inspection or fixing. Either the adhesive joint between carbon fiber and titanium end caps or the hull itself were probable failure points, both prone to differential thermal expansion and cumulative fatigue when placed under deep-sea conditions.

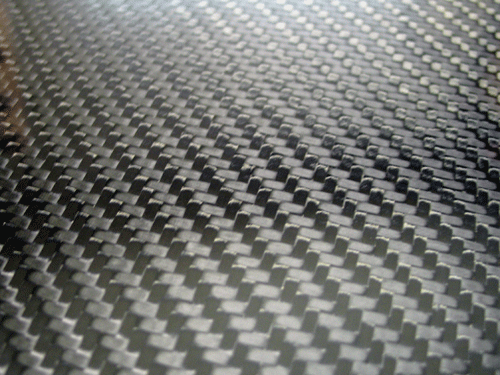

3. The Science of Carbon Fiber Under Pressure

Carbon fiber composites are touted for their strength-to-weight ratio in aerospace and applications under internal pressure, but carbon fiber’s behaviour under external compression is less reassuring. “Carbon fiber is very strong in tension but less strong in compression,” Chung said. Externally, deep-sea submersibles are subject to pressures over 4,900 psi at Titanic depths, which increase risks of delamination and catastrophic failure. Thermal cycling traversing from warm surface waters to near-freezing depths arepeatedly introduces extra stress at material interfaces, especially where carbon fiber interfaces with titanium. As Dr. Samantha Rodríguez pointed out, “Each thermal cycle potentially degraded the critical bond strength at the titanium-carbon interface,” an aspect that was overlooked in Titan’s design and maintenance regime.

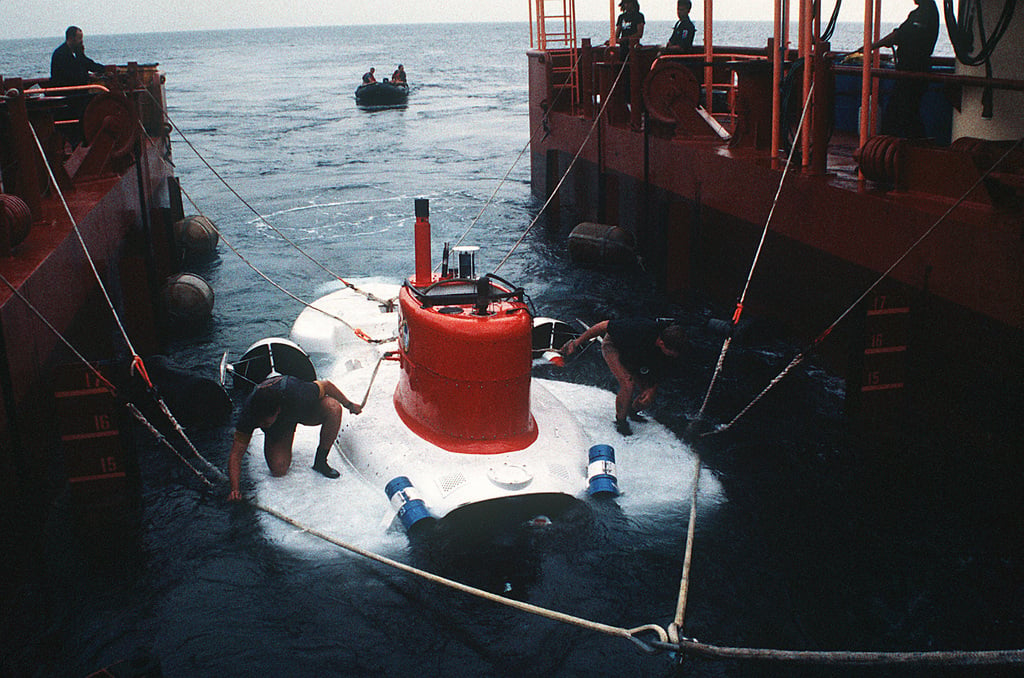

4. Certification, Inspection, and Industry Standards

In contrast with well-established deep-sea vehicles, Titan never received any registration, certification, or inspection by any approved classification society. Industry experts and organizations including the American Bureau of Shipping and Lloyd’s Register maintain strict protocols for design review, pressure testing and operational inspection of crewed submersibles. “We have a very high confidence in the strength of what’s been built,” said Chase Hogoboom, president of Composite Energy Technologies, whose carbon fiber pressure vessels for unmanned underwater vehicles are tested to failure and monitored for cycling fatigue. OceanGate, on the other hand, “skipped” these measures, eschewing third-party certification and recurring non-destructive testing like ultrasound scanning that might have caught microcracks.

5. Regulatory Oversight and Lost Opportunities

The Coast Guard report cited a “regulatory vacuum” that permitted OceanGate to run Titan outside of existing safety guidelines. By strategically creating and exploiting regulatory confusion and oversight challenges, OceanGate was ultimately able to operate Titan completely outside of the established deep-sea protocols, the report said. It added that a whistleblower complaint from 2018 detailing issues with carbon fiber hulls was not acted on by OSHA and the Coast Guard, a “lost opportunity to take action.” The board’s suggestions now demand required Coast Guard record-keeping, increased federal and international standards, and a new understanding between OSHA and the Coast Guard to clarify whistleblower procedures and enhance coordination.

6. Workplace Culture and Operating Failures

Beyond technical flaws, the investigation uncovered a “toxic workplace environment” at OceanGate, where staff were fired or threatened for raising safety concerns. Financial pressures led to deferred salaries, reliance on contractors lacking critical knowledge, and decisions that compromised safety. The company’s leadership, according to testimony, prioritized “customer expectations and financial constraints over engineering integrity,” with Rush’s public claims of an “indestructible” hull providing a false sense of security for both passengers and regulators.

7. Lessons for Future Deep-Sea Engineering

The Titan disaster has stimulated the maritime engineering community to re-examine optimal practices for submersible design, materials, and regulation. Scientists are now working on improving composite layups with thermal-expansion-matched properties, creating gradient interfaces, and employing real-time strain measurement. There is renewed emphasis on third-party certification, non-destructive testing, and the use of fracture-resistant thermoplastic composites, which laboratory tests show can withstand over 600 bar of pressure. As Oleksandr Kravchenko of Old Dominion University noted, “Composites can be safely used in submersibles if guided by sound engineering practices,” but thermoset prepregs are “relatively brittle and prone to delamination under extreme environmental loading” a susceptibility that the Titan disaster had exposed.

The 17 recommendations of the Coast Guard, such as the strengthened communication protocols, obligatory dive and emergency response plans, and wider international safety requirements, mark a watershed moment for the industry. The tragedy of the Titan’s sinking, although awful, is now leading to a new era of stringency, openness, and creativity in deep-sea exploration.