The Chinese plan to finish the preliminary model for the international lunar research station by the year 2035 is more than a milestone in their space policies. During the Deep Space Exploration Laboratory Symposium, Chen Jie, a representative from the Chinese Academy of Engineering, discussed the key for the establishment of the lunar base: in-situ resource utilization in the lunar environment, intelligent manufacturing through the help of clustering effects, and the ability for fully automated intelligent operations. These concepts today are transformed through prototypes and laboratory tests to conquer the extreme conditions present in the Moon.

1. In-Situ Lunar Soil 3D Printing with Solar Energy

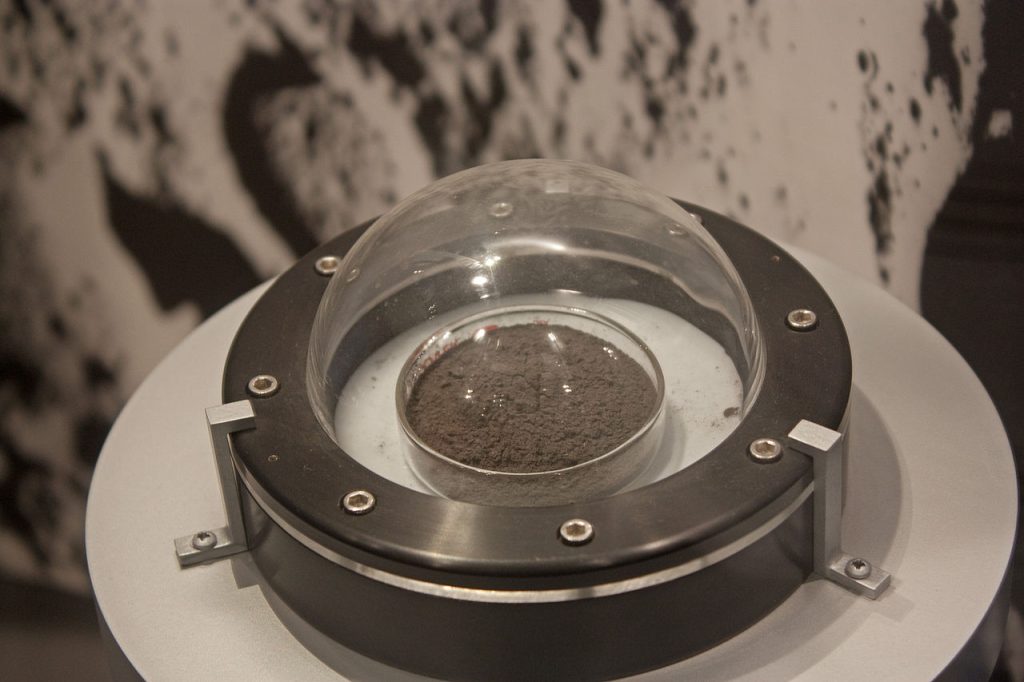

The lunar soil brick-maker in the DSEL is an enormous step forward in In-Situ Resource Utilization (ISRU). Through the concentrated solar energy that is focused via parabolic mirrors and then transmitted via ablation-resistant fiber bundles, the melting of the lunar soil exceeds 1300 °C. Sintering of powder and powder bed fusion are then used to create dense bricks from the melted masses without any additives. The team liked to test the printer on several different kinds of lunar soil analogs to ensure that it worked on both basaltic mare and feldspathic highland types. It tackles the monumental transportation problem of construction materials from earth and is also consistent with the primary objective of ISRU.

2. Ultra-Fine Continuous Lunar Regolith Fibers

Based on the Chang’e-5 return materials, continuous fibers with a diameter of 10-20 μm were produced via a high-temperature melting and vacuum drawing process at Donghua University. A set of automatic fiber production facilities was designed for a high vacuum and microgravity environment, making it possible to fabricate composite materials inside the facilities. The tensile strength of lunar regolith-derived basalt fibers could reach ~1400 MPa, and corrosion and heat-resistant capabilities could surpass metals, which was proved by some experiments related to the production of basalt fibers.

3. Engineering for Lunar Environment Extremes

Factors on the Moon’s surface include severe temperature variations ranging from +127°C and −183°C, low pressure (about 10⁻¹² Pa) and strong vacuum conditions, dust particles, and strong radiation levels of up to 60 µSv per hour. Operational environments for manufacturing systems are challenging. Prototypes developed at DSEL take measures to counter temperature and dust problems and have vacuum-resistant actuators. Materials used are established radiation-resistant composites and geopolymer binders that have been tested in lunar.

4. Swarm Intelligence for Heterogeneous Robot Clusters

Chen Jie’s vision includes terrain mapping by survey robots, transport of regolith by transport robots, component stacking by 3D printing robots, and assembly by assembly robots. For this to be achieved, it will need to be facilitated by swarm intelligence, which could be based on biological processes. The Lunarminer shows the concept of division of labor and flashing signals could decrease resource extraction time by 40% and energy by 31%.

5. High-Precision Collaborative Positioning

Reliable coordination under the conditions found on the GPS-denied Moon requires highly accurate positioning. Some ideas involve decentralized time division multiple access (TDMA) communications systems, orthogonal frequency division multiplexing (OFDM) for resolving multipath effects, as well as multi-mode antennas for 3D bearing analysis. Such technologies allow robots to position down to within centimeters, which is necessary for building large structures out of 3D-printed components of regolith.

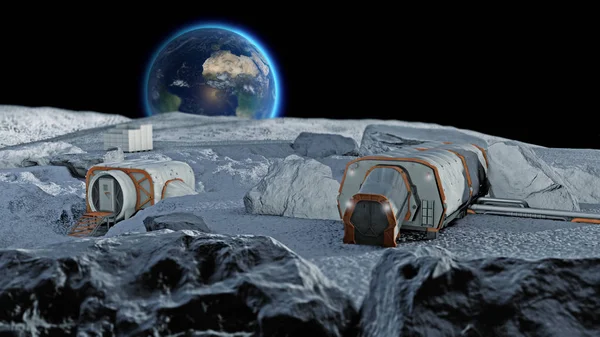

6. Habitat Module Integration

Lunar soil bricks shall function mainly as exterior protective coverings, integrated into rigid pressure-resistant or inflatable modules. The techniques of hybrid construction consider the architectural needs of the structure on a lunar setting, taking into account the structure’s stability, thermal insulation, as well as the shielding of the structure against micrometeorites. Verification of the structure involves the whole testing process, ranging from brick manufacture to the loading test of the structure before its deployment on the moon.

7. Radiation Resistant Infrastructure Materials

Radiation shielding is a concern for crewed bases. Basalt fiber composites, sulfur concrete, and sintered regolith blocks have been studied for attenuation coefficients. The geopolymers formed from low-alkali regolith simulants retain strength under vacuum conditions and temperature cycling, which makes them amenable for radiation shielding as well as as structure material.

8. International Collaboration and Deployment Schedule

ILRS has both surface and orbital components, which are initiated by China. The basic model in the lunar south pole area will be completed in the 2035 timeframe, while the extended model will be in the 2040s. As of April 2025, there are currently 17 countries as well as more than 50 research institutions that are members of ILRS, making it an international engineering effort.

Through the integration of ISRU-based manufacturing, fiber-reinforced composites, swarm intelligent robotics, and precise positioning, China’s plan for the construction of their lunar bases encompasses all the challenges, both environmental, logistical, and operational. These technologies not only serve as the backbone for the ILRS initiative but also for other missions involving the development of deep-space infrastructure.